DIGITIZING THE ROOFTOP

In 2015, solar field engineers collected and recorded technical rooftop information with a sheet of paper, a pencil, and a Suneye. By 2016, the Suneye, an essential piece of equipment, was going off the market.

I was part of an ambitious project to replace the Suneye, and redesign the process for collecting rooftop information.

OVERVIEW

Since launching in 2007, Sungevity has become one of the largest solar companies in the world. By 2016, Sungevity operated in 13 states and 5 countries. The company has a dedicated internal sales team, and an extensive network of local installers that partner with Sungevity to get panels on the roof. After a system is sold, Sungevity’s primary job is to provide installers with the software and tools that make installing solar at scale possible.

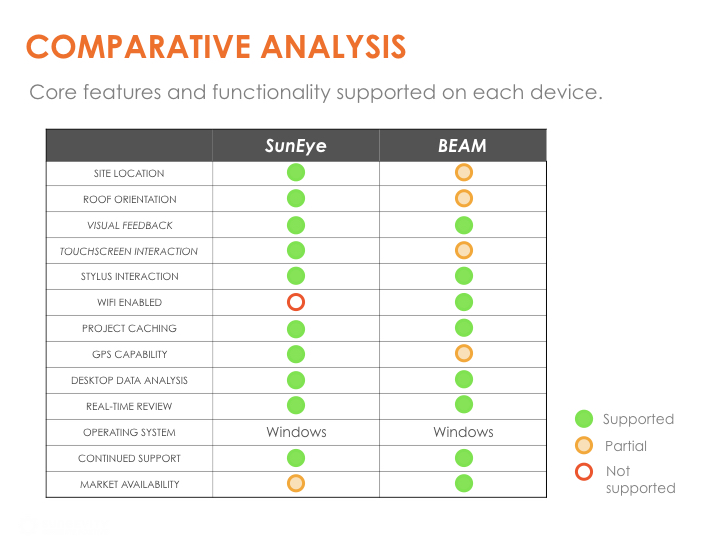

One critical tool Sungevity provided was the SolMetric SunEye 210 – an industry-specific tool used to measure the solar potential of a customer’s roof. In 2015, a competitor acquired Solmetric and planned to remove the SunEye from the market.

THE CHALLENGE

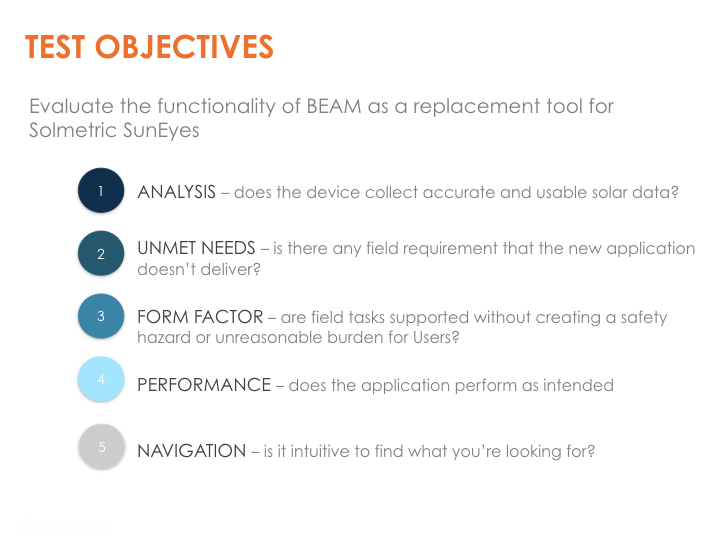

Our initial goal for the project was to replace the SunEye with a tool built in-house within 4 months (design, test, and deliver). Other offerings on the market were unreliable, and installers were quick to object any that were put on the table. In addition, we believed developing our own product would open up opportunities to innovate other points in the installation process. Our ambition was to develop a reliable tool for measuring solar potential, while creating a strong platform for digitizing the site visit overtime.

The original Solmetric SunEye 210

BEAM at product launch in 2016.

MY ROLE

I led the design, strategy, and experience of the software. For the first phase of the project, I worked closely with a Software Engineer and Hardware Engineer on the development of the product and collaborated with stakeholders in operations department to clarify business goals and negotiate scheduling for user interviews and usability testing. In Phase 2, once we had company buy-in to develop the product further, I worked closely with a Visual Designer to build out the rest of the product. We delivered the full product to our network of solar installers in June 2016. A third phase of the product focused on product improvements and incorporating additional functionality.

UI mockups and prototyping

Usability testing

Project Management

Product and user research

Persona development

User journeys, task flows, wireframes

DESIGN PROCESS

Project Kickoff

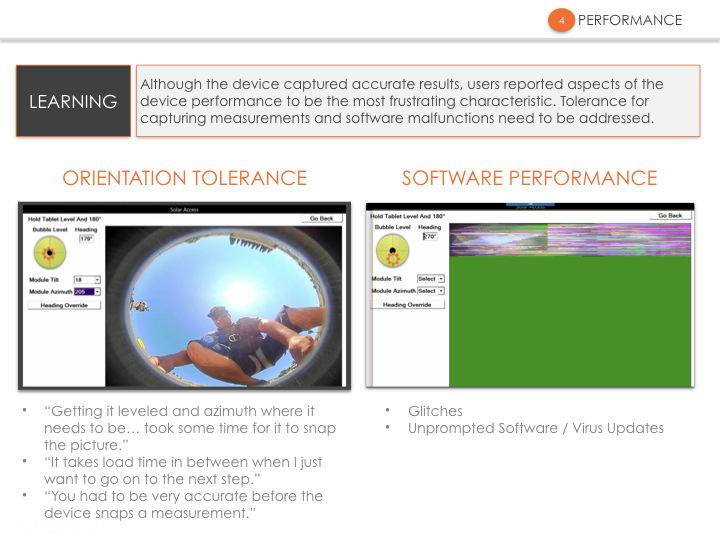

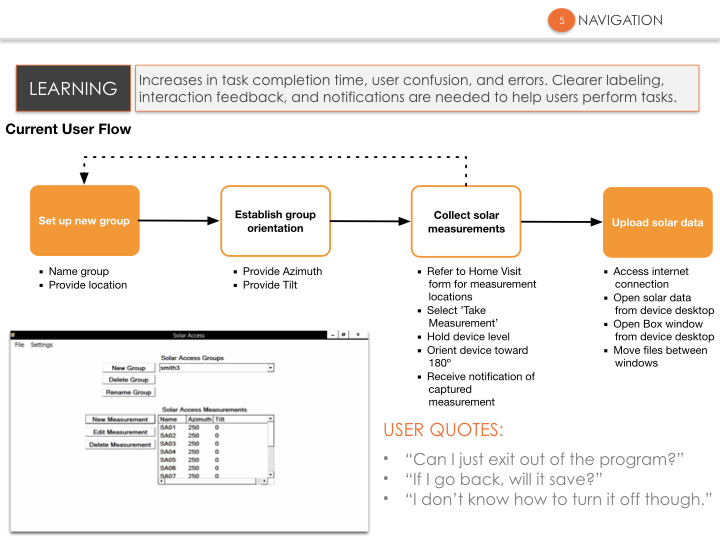

At the outset of the project, our objective was to investigate the viability of a new solar measuring tool. Due to various business and technical constraints, we were presented with some unique challenges. Dependencies further down the organization’s technology stack required a specific programming language (C#), limiting our hardware options to a tablet running Windows. In addition, we would have to add on a fisheye lens camera to effectively capture solar readings. This meant adding additional hardware and protection around the frame of the tablet. Once we had a basic prototype of both the software and hardware, it became critical to go into the field to evaluate our Home Visit Technicians’ ability to use the tablet while performing the key functions of their job. In addition, we would leverage the opportunity to collect insights for innovating other areas of the site assessment.

Initial “out of the box” interface

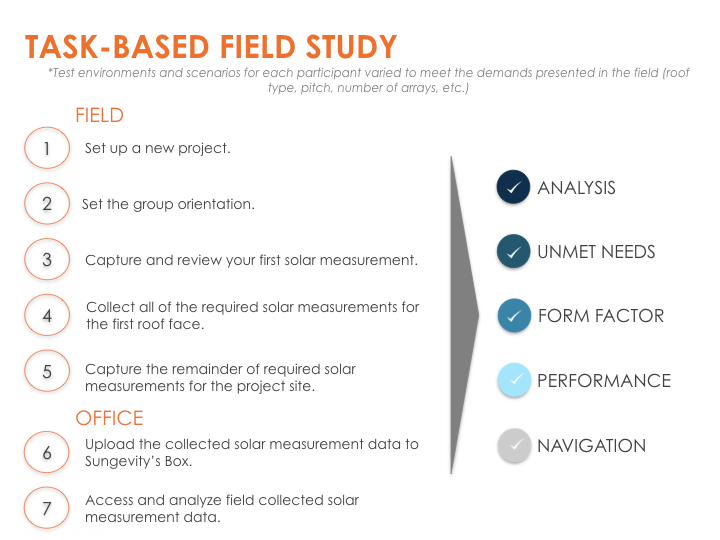

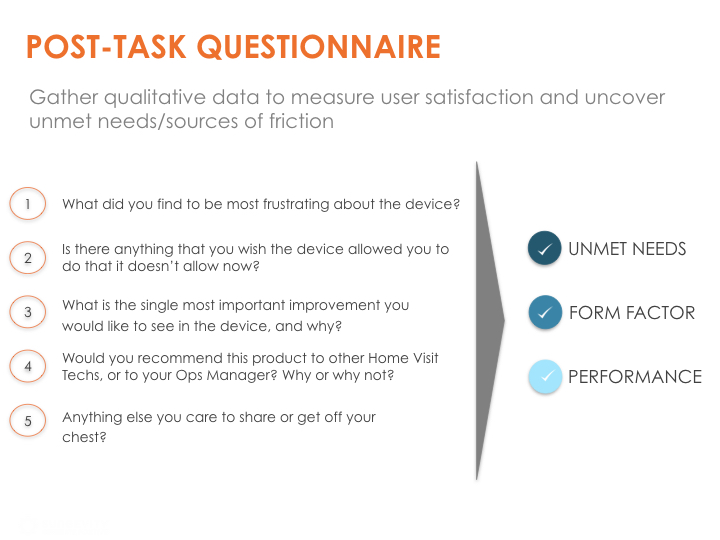

Research

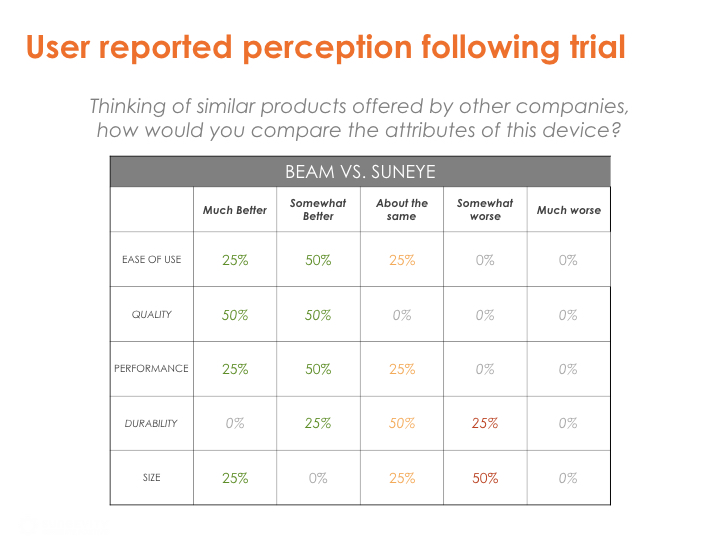

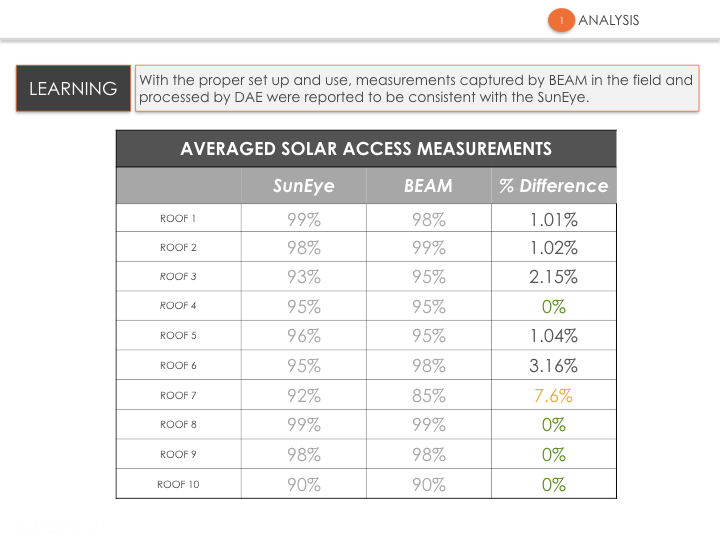

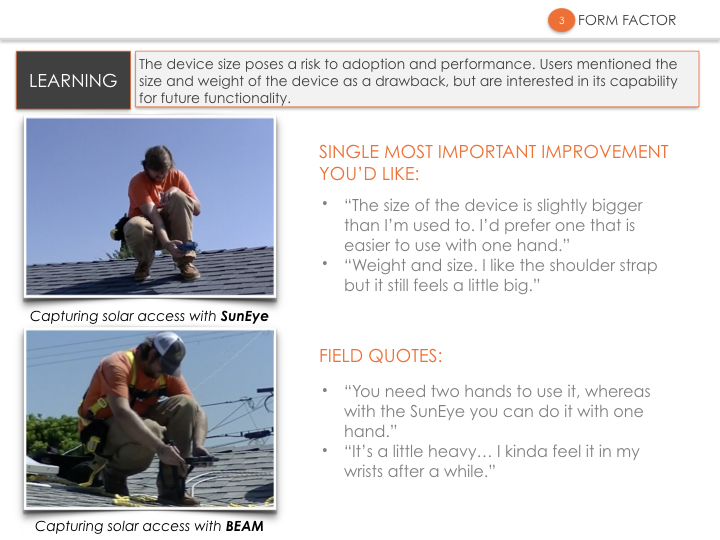

We partnered with installers in San Diego, an area with high variability of roof types, to test the solar reading tool at 10 home visits. Our goals were to validate the effectiveness of the shading tool against the SunEye, and to understand the challenges Home Visit Technicians faced. We had the users capture readings with both the original SunEye device as well as our prototype in order to validate the accuracy of the readings. The trial also revealed some immediate experience gaps to plug before expecting users to adopt of the product.

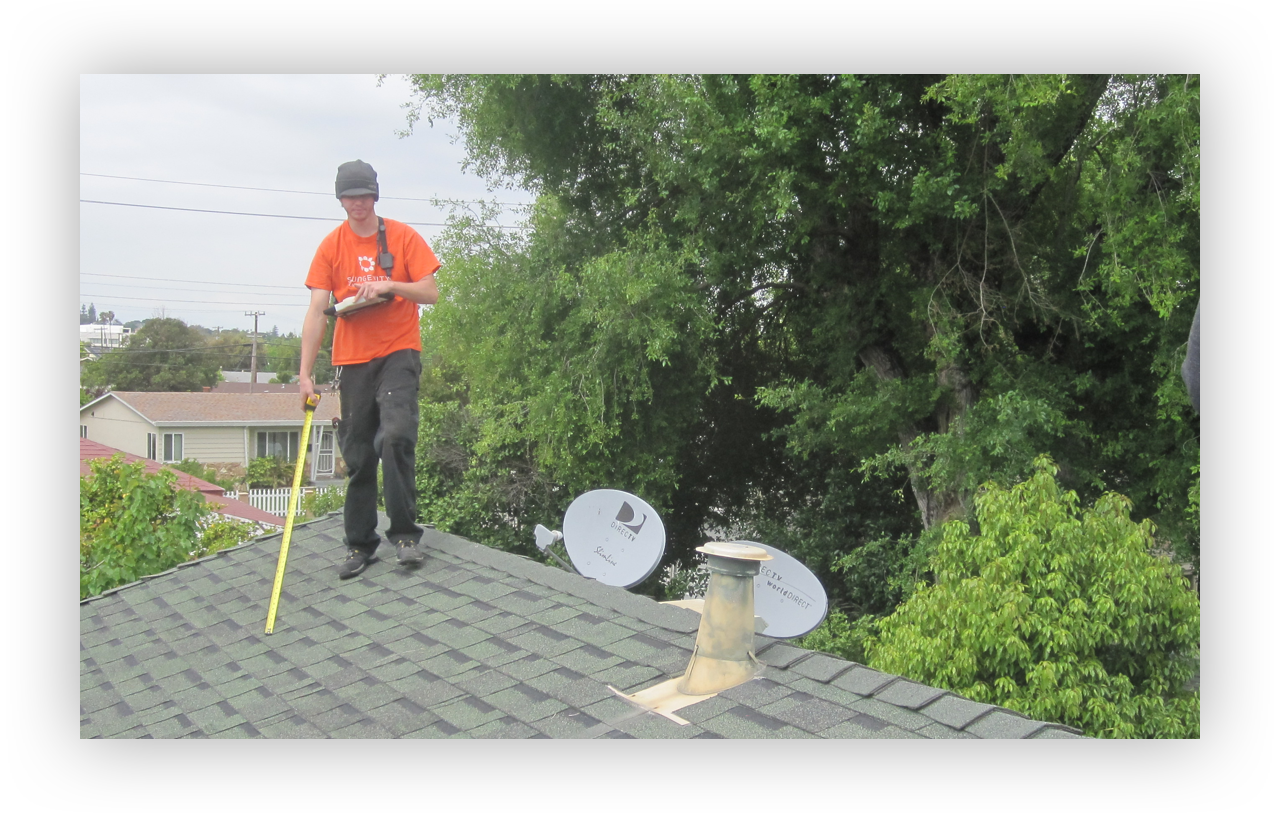

Collecting field research for the initial product.

Additional Information Required

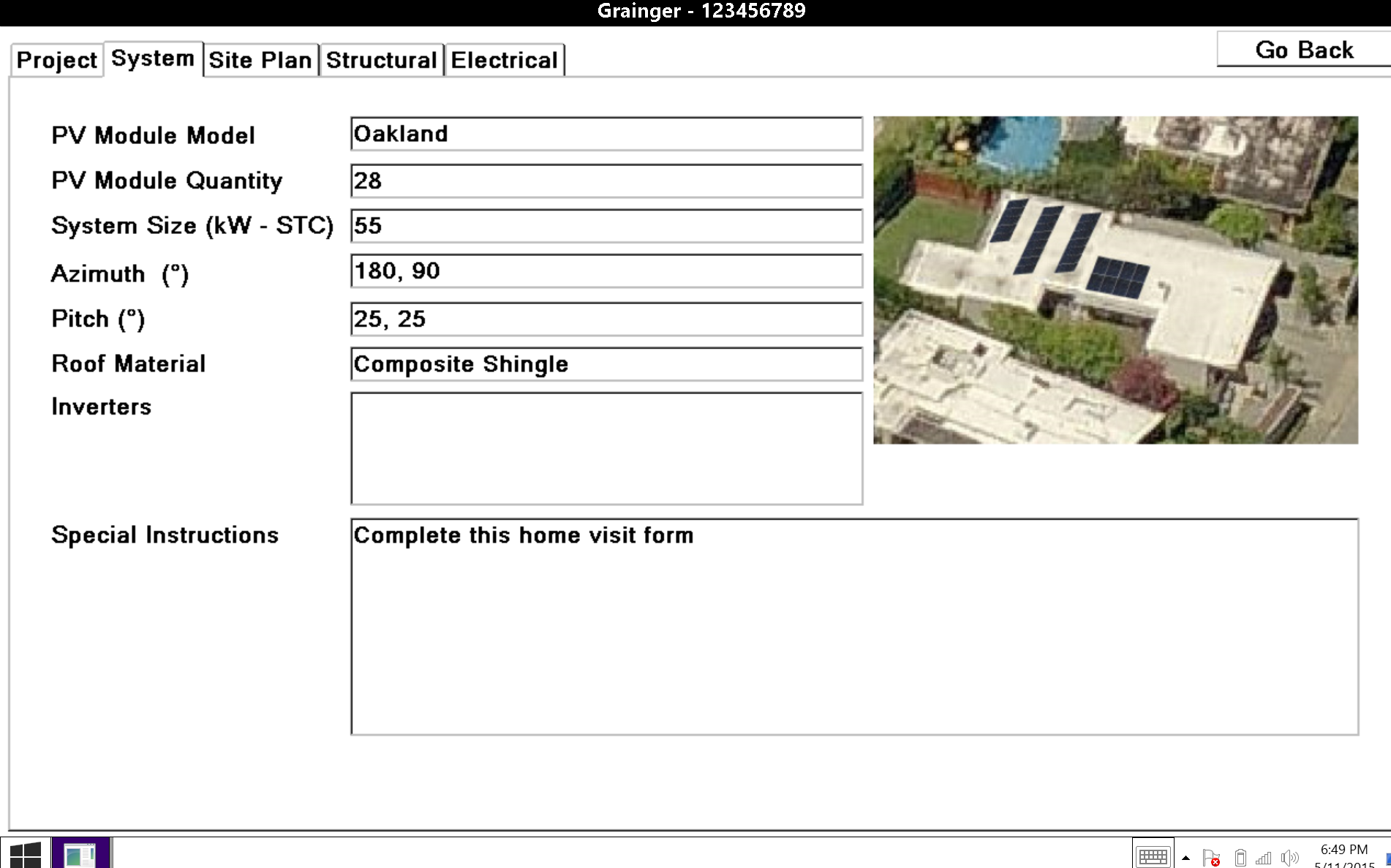

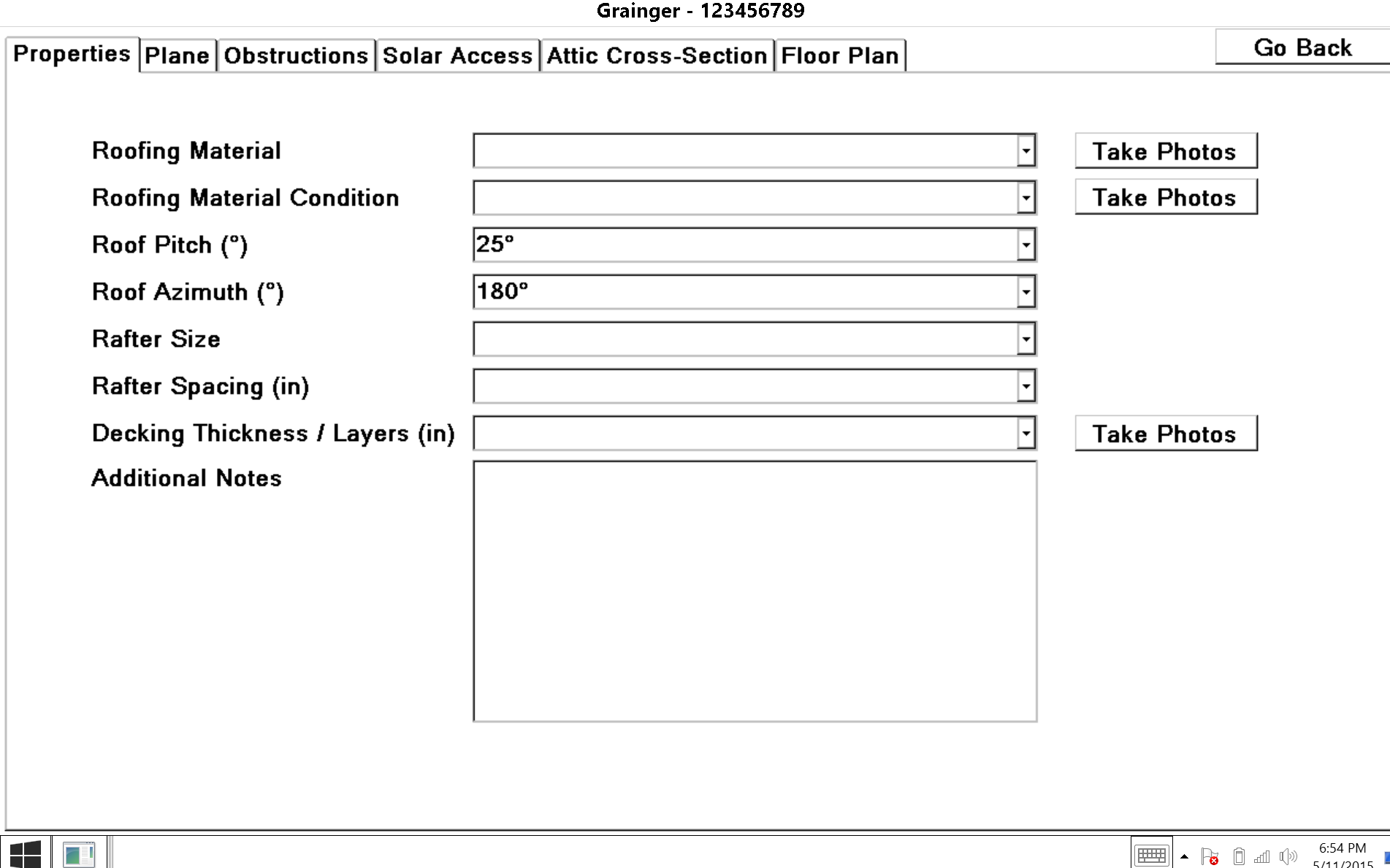

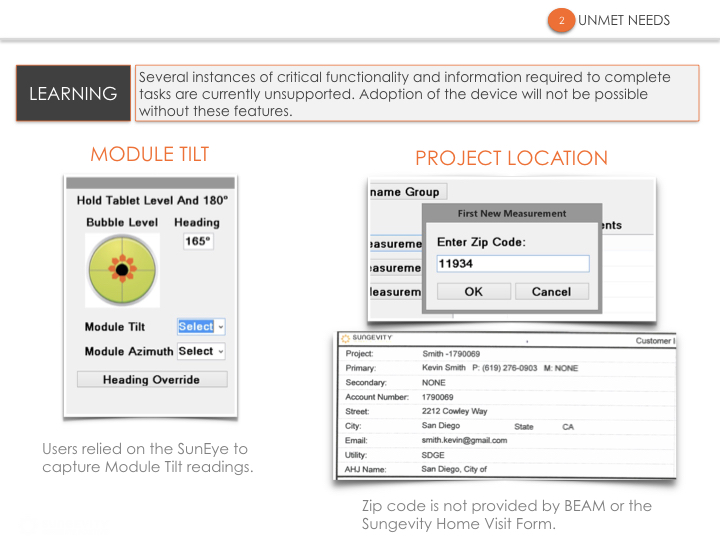

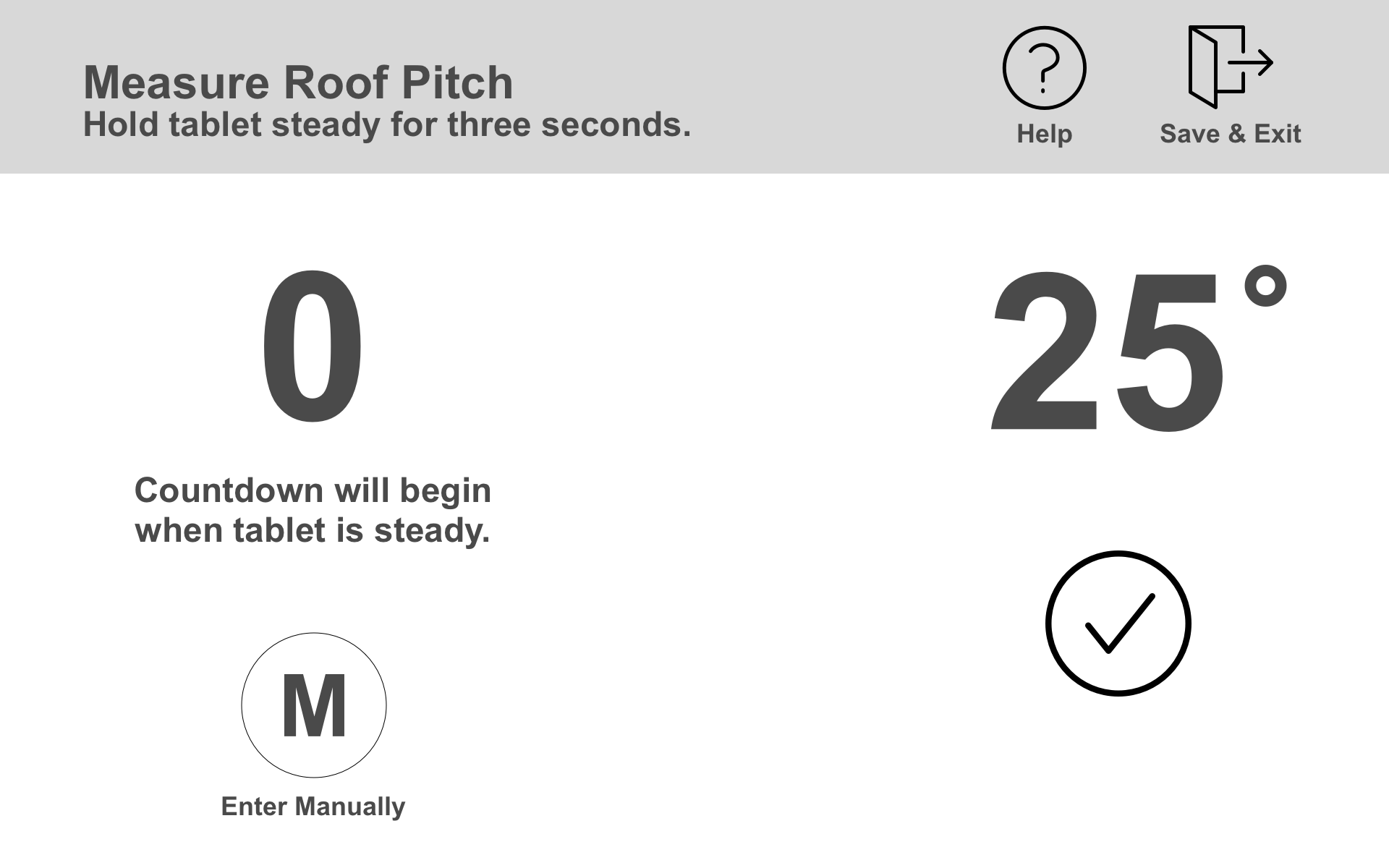

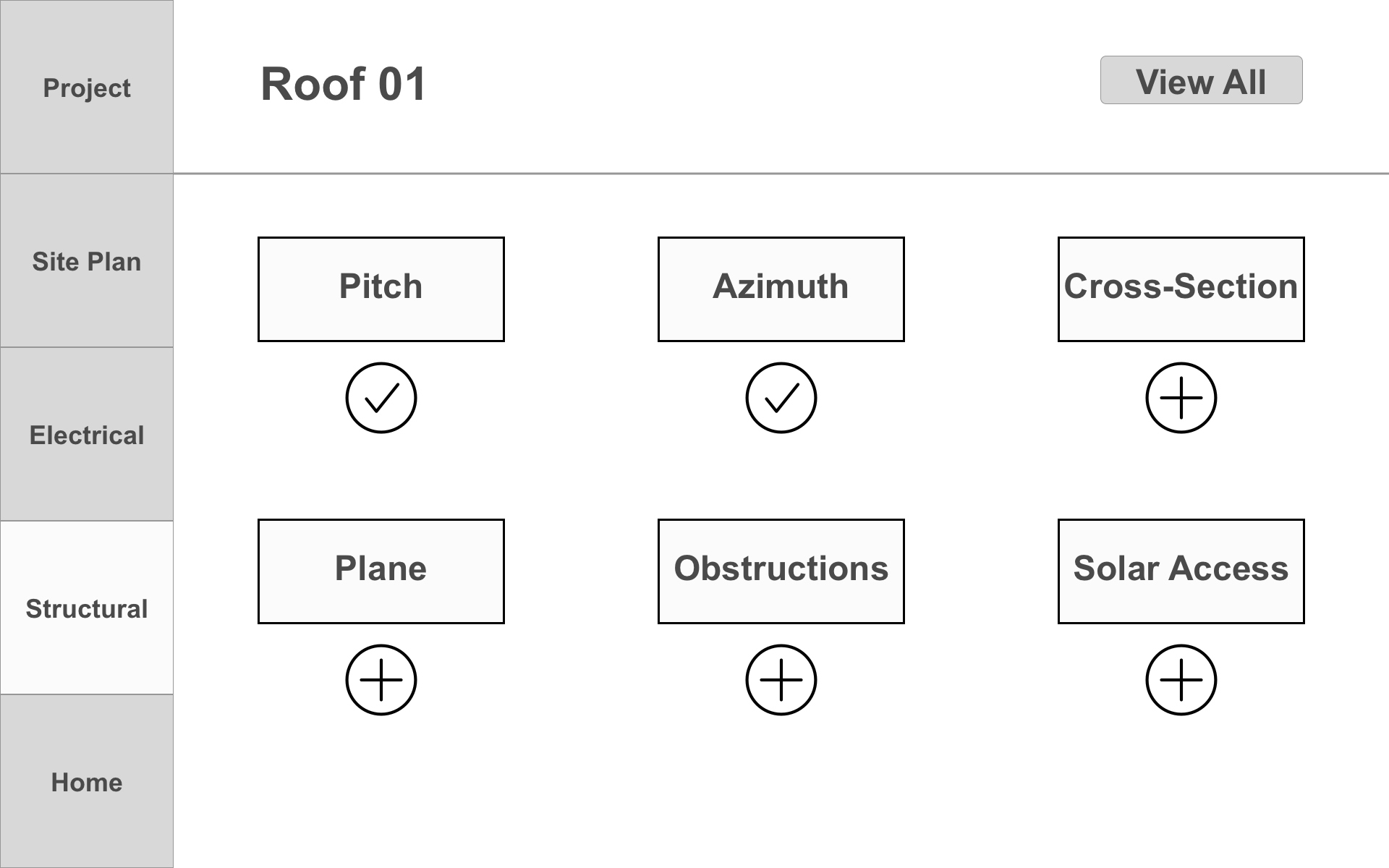

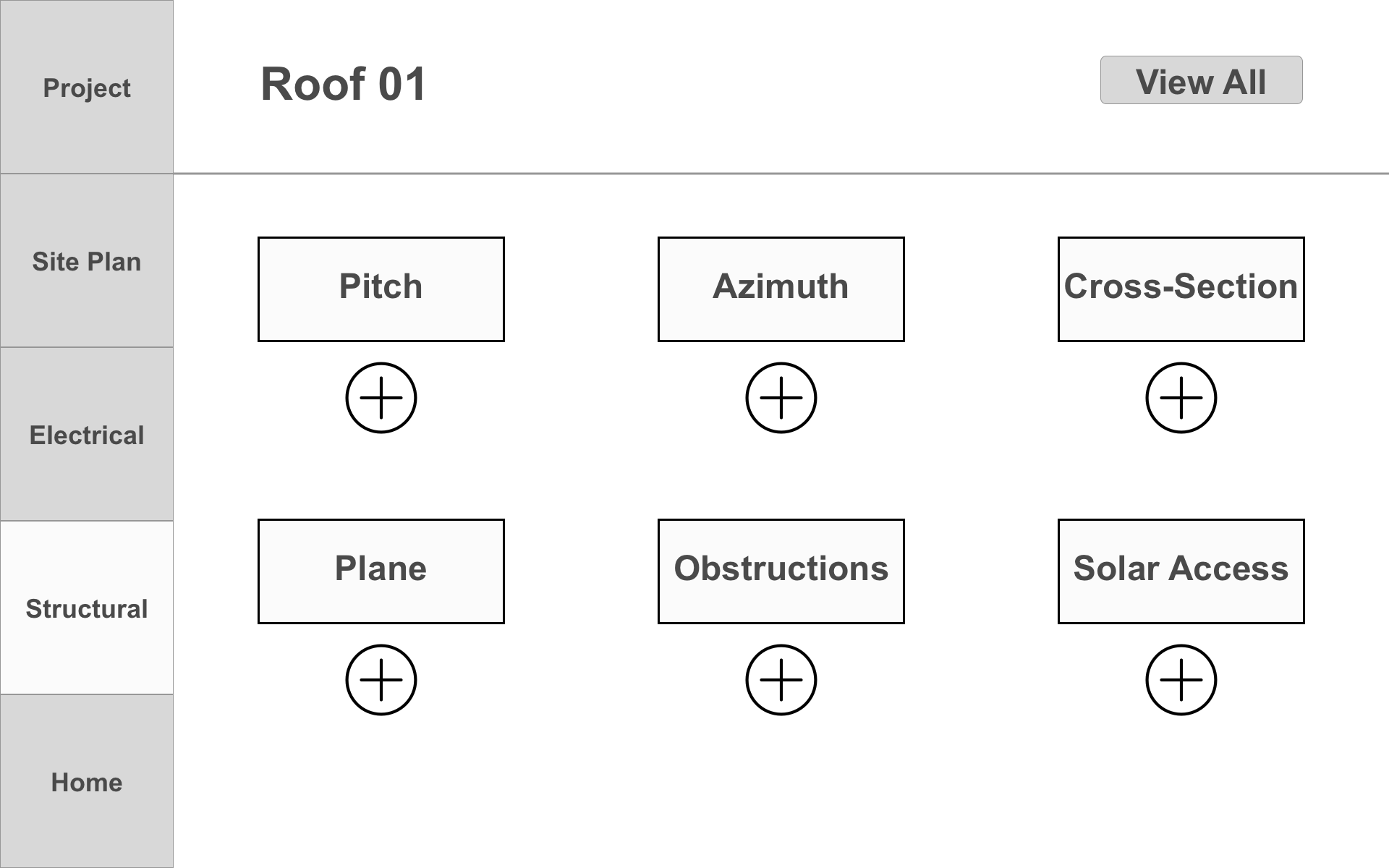

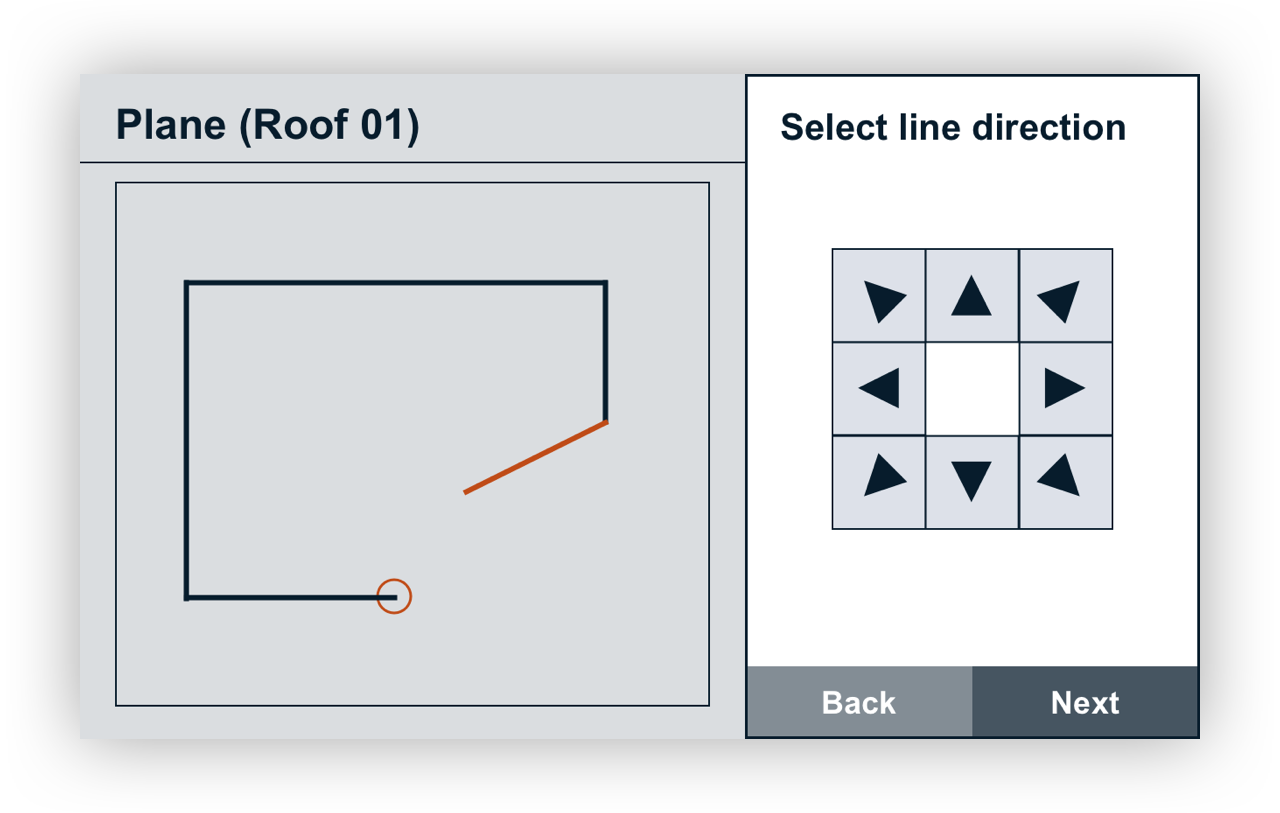

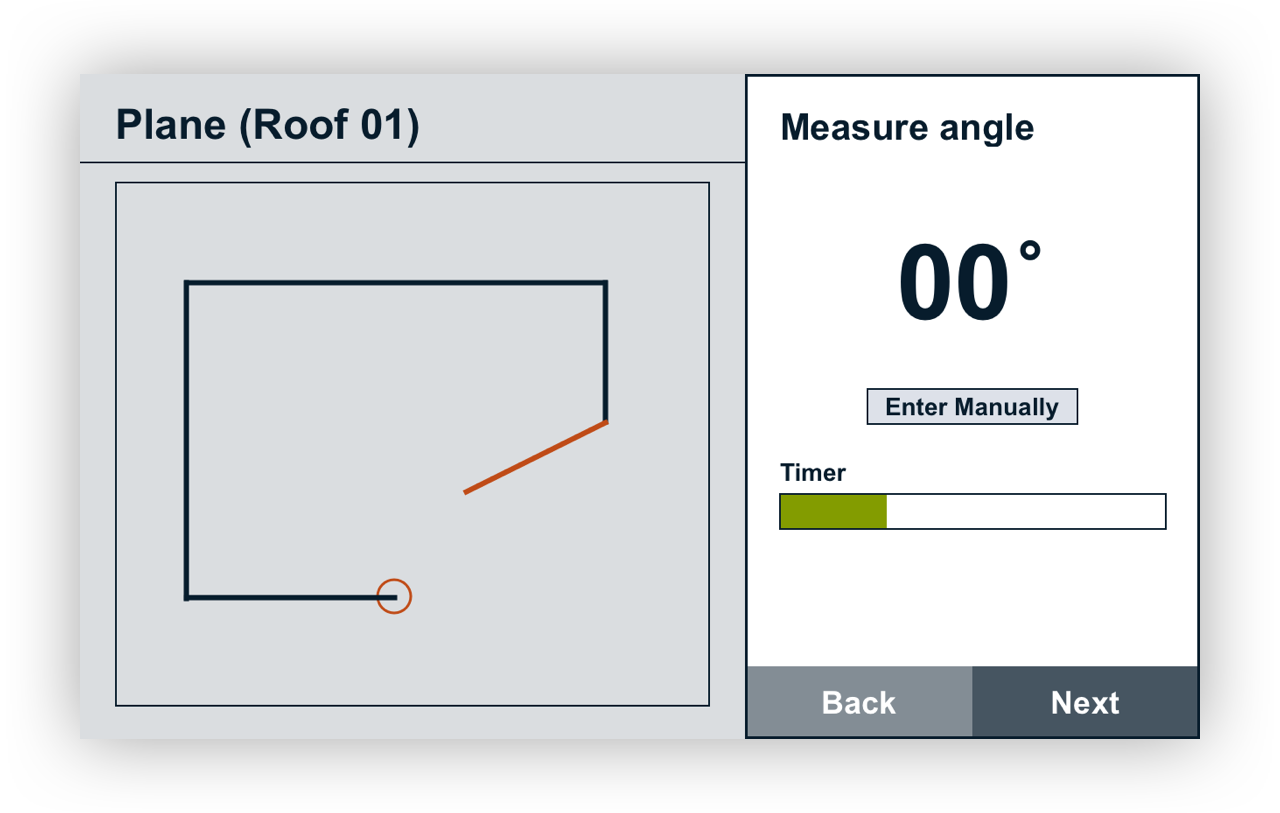

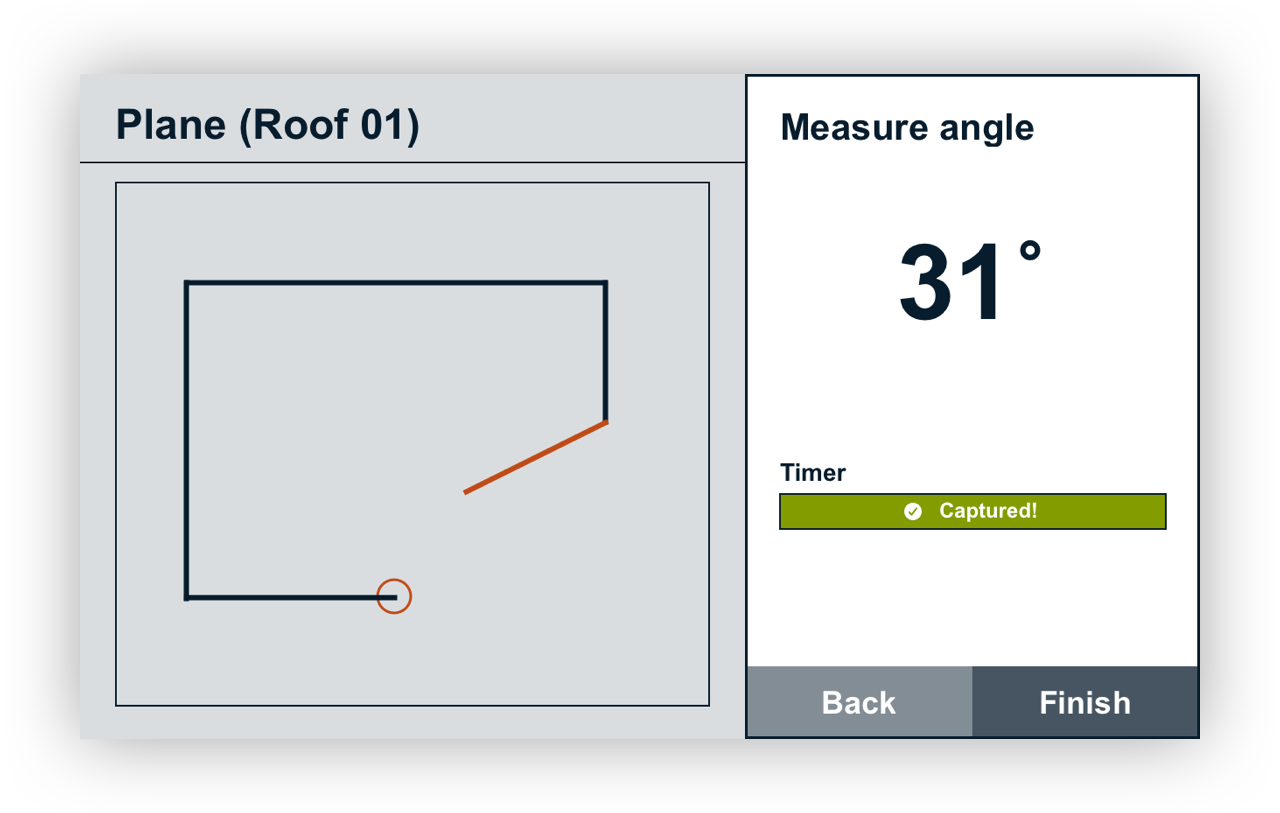

Accurate solar readings require Roof Pitch (slope) and Azimuth (roof orientation toward the sun). We had to come up with a reliable interaction for capturing these measurements with the device.

Lack of Performance Safeguards

Techs often had different approaches to the way they collected solar readings – standing upright, crouching, or putting the device directly on the roof. Each approach resulted in varying measurements, and a greater potential for error. The SunEye lacked features to prevent or mitigate human error.

Discovery

Beyond Sun and Shade

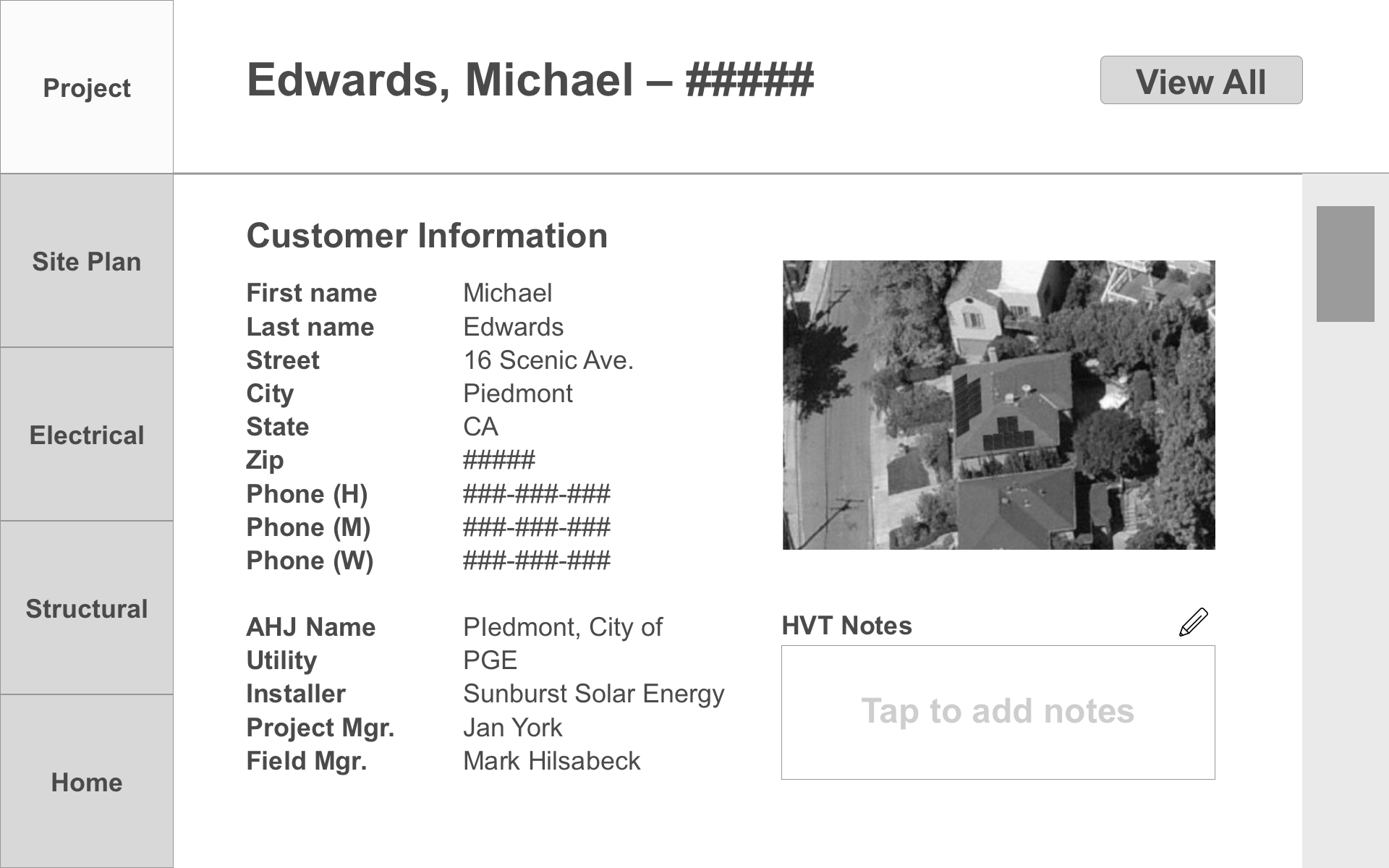

Shadowing the Home Visit Techs through the entire site assessment revealed some surprising insights. We were satisfied with the performance of the device’s ability to capture solar measurements, but field research quickly uncovered greater opportunities for improving the Home Visit Tech’s entire workflow. Where paper and pencil presented a significant burden and source of error, our new device opened doors for digitizing the site assessment.

Burdened with Equipment

Techs were concerned about the possibility of adding another piece of equipment to their routine. Techs expected the new tool to perform more than one role if they were going to use it, creating a net reduction in the number of tools required to perform their job.

Tight, Uncomfortable Spaces

One of the unique challenges to the job is accessing and collecting information inside of a customer's attic. Entry points are small, limiting a techs ability to utilize the tools they bring along to record details. In addition, the spaces often reach temperatures above 100º Fahrenheit, making it one of the most frustrating steps of the Home Visit Techs job.

Measure, Mark, Repeat

Home Visit Techs spent most of their time on the roof with a tape measure, recording every edge of the roof. They used paper and pencil, which was scanned and often misinterpreted back in the home office.

Spray and Pray Photo Collection

Home Visit Techs were provided with a small digital camera and required to take photos of various equipment, obstructions, and information for the field office and installers. Rather than miss an important photo, the technicians erred on the side of volume and took dozens of photos. Each photo album had to be uploaded in the office and sorted by another team member in the home office.

Information Delivery

Techs weren’t equipped with the ability to send information from the job site. Data uploads took place in the field offices, which often delayed projects by multiple days.

Summary and Presentation of Field Test

Additional Personas

Primary Persona

Research-based persona developed from Field Test

Ecosystem of users impacted by BEAM

Reframing the Problem

These issues were creating downstream installation problems. Not only were errors impacting the work of Home Visit Techs, but also the Project Managers back in the offices reviewing the data. Incorrect or misinterpreted information required Home Visit Techs to return to the job site and verify or update the work they had done. With this realization, we took a step back to define what problem we could solve.

“How might we help Home Visit Techs in the field and Project Managers in the office communicate project information faster and more reliably?”

Our solution was BEAM, a device for digitizing the entire site assessment on behalf of Home Visit Technicians and Project Managers.

Rapid Wireframing

With the support of the organization and our new “How might we?” statement, I worked with a visual designer to completely reinvent the interface from a structural level. The business approved the addition of a front-end developer familiar with the Windows platform, so we could invest more energy toward layout with the increased understanding of technical feasibility. As we iterated on the layout, we continued to invite local installers in to test and review progress, testing our biggest assumptions along the way.

Solutions and Mockups

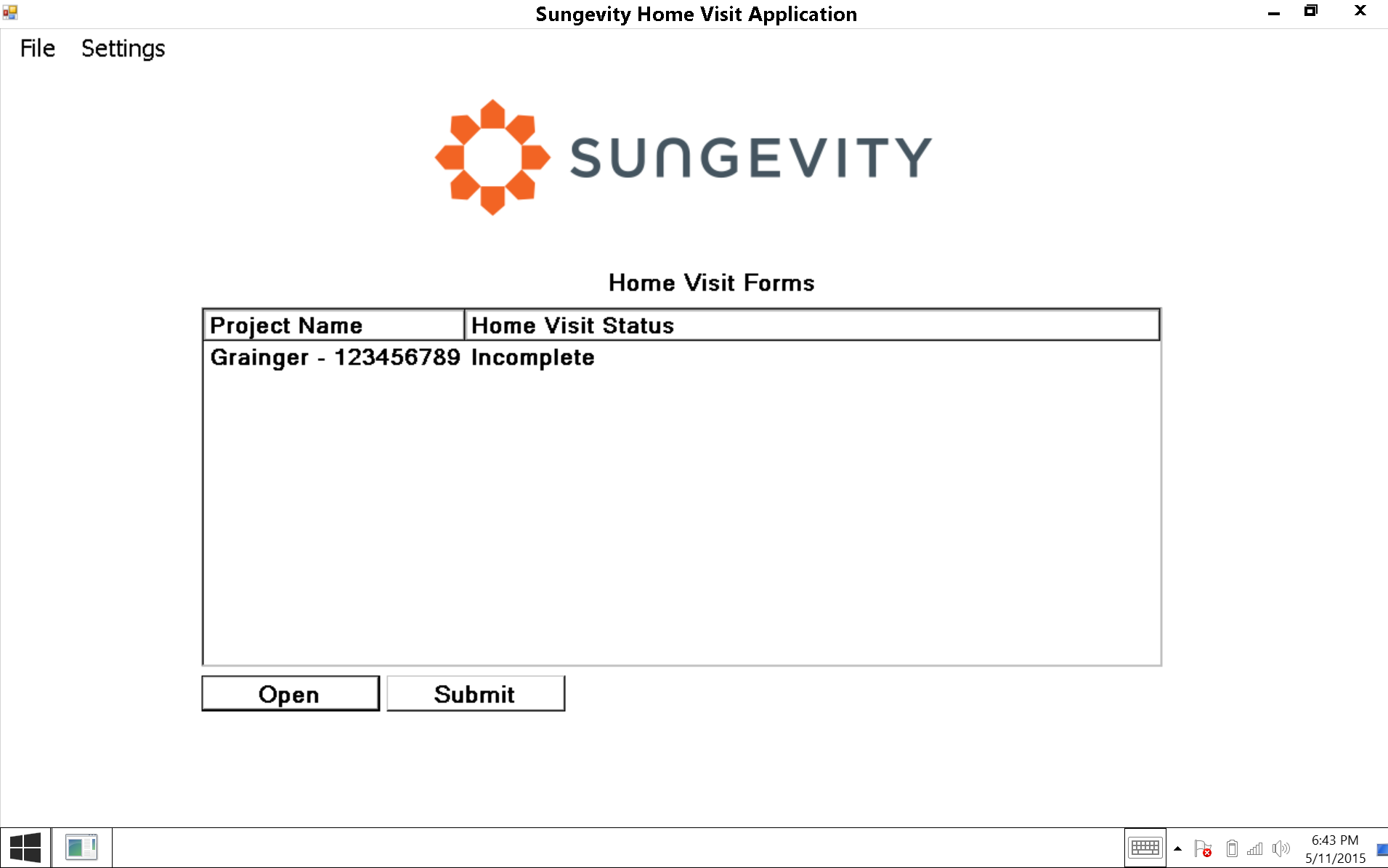

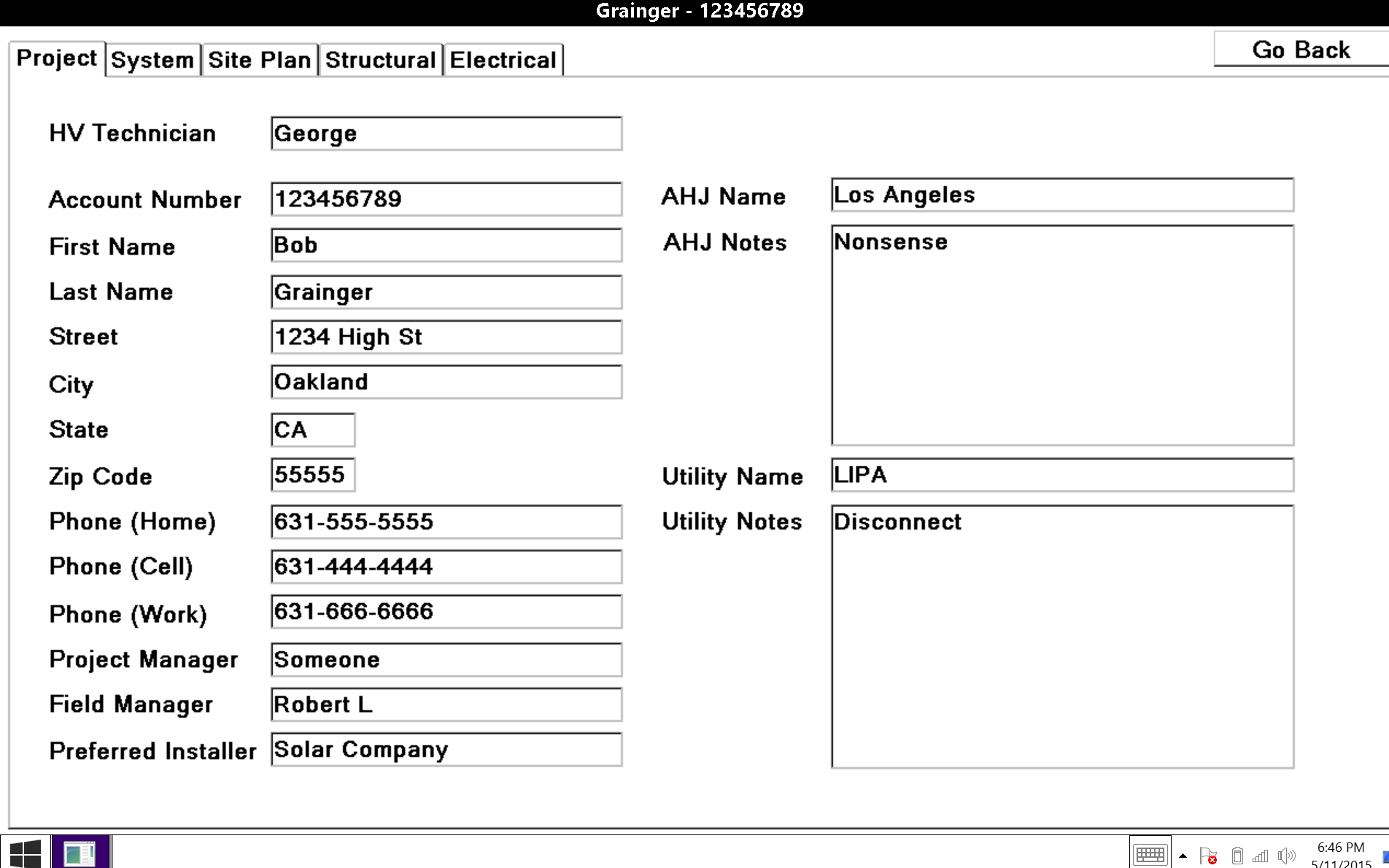

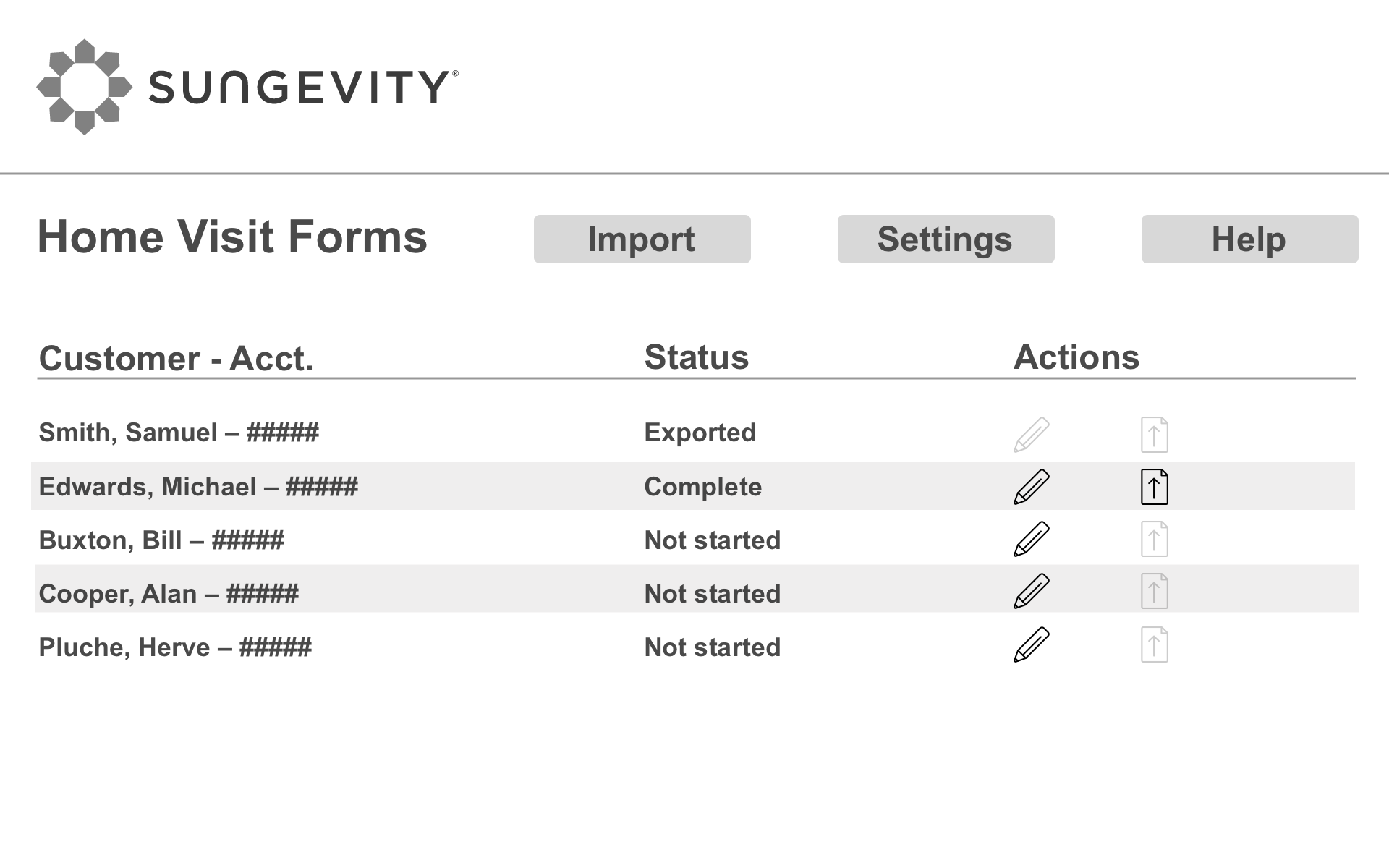

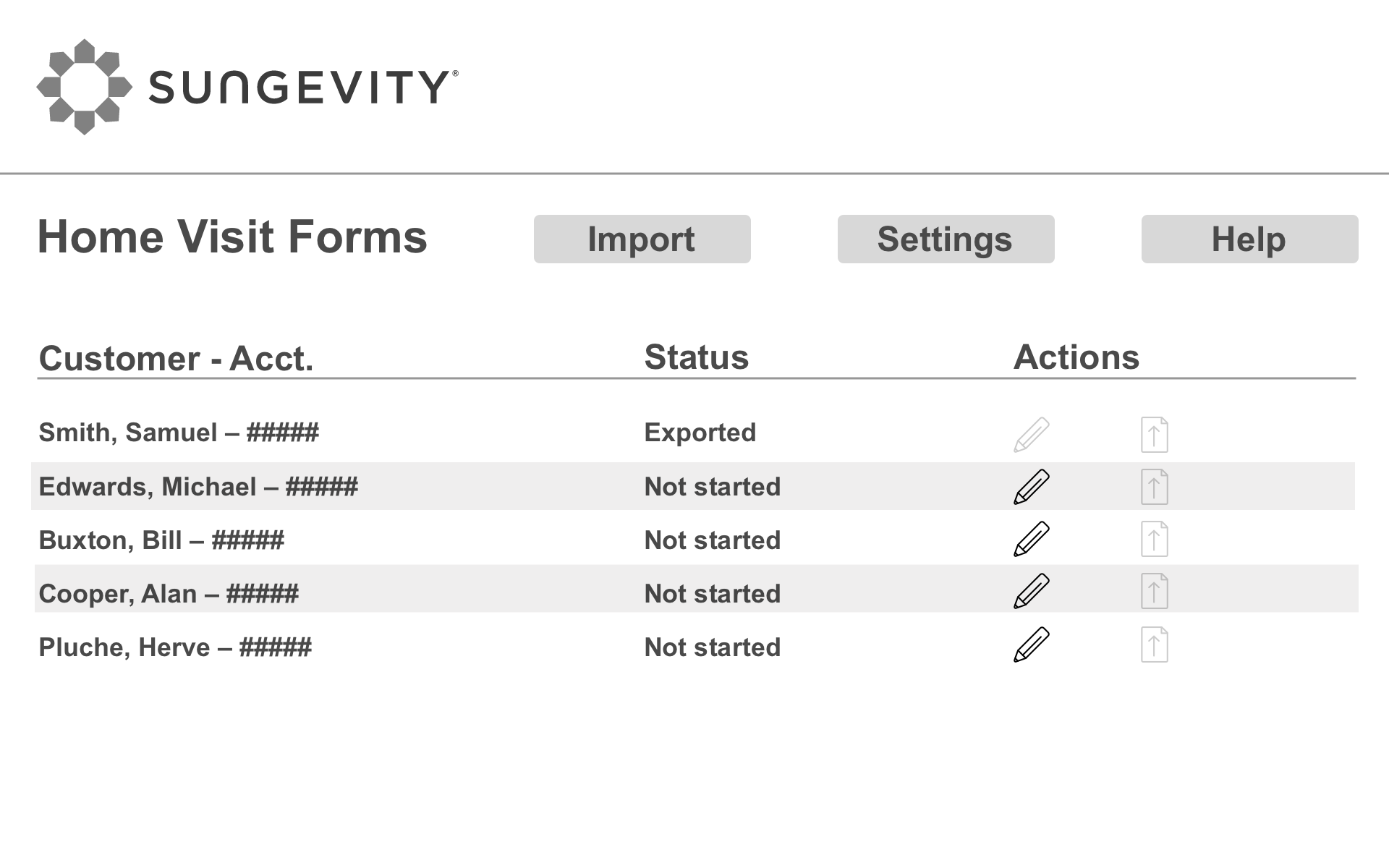

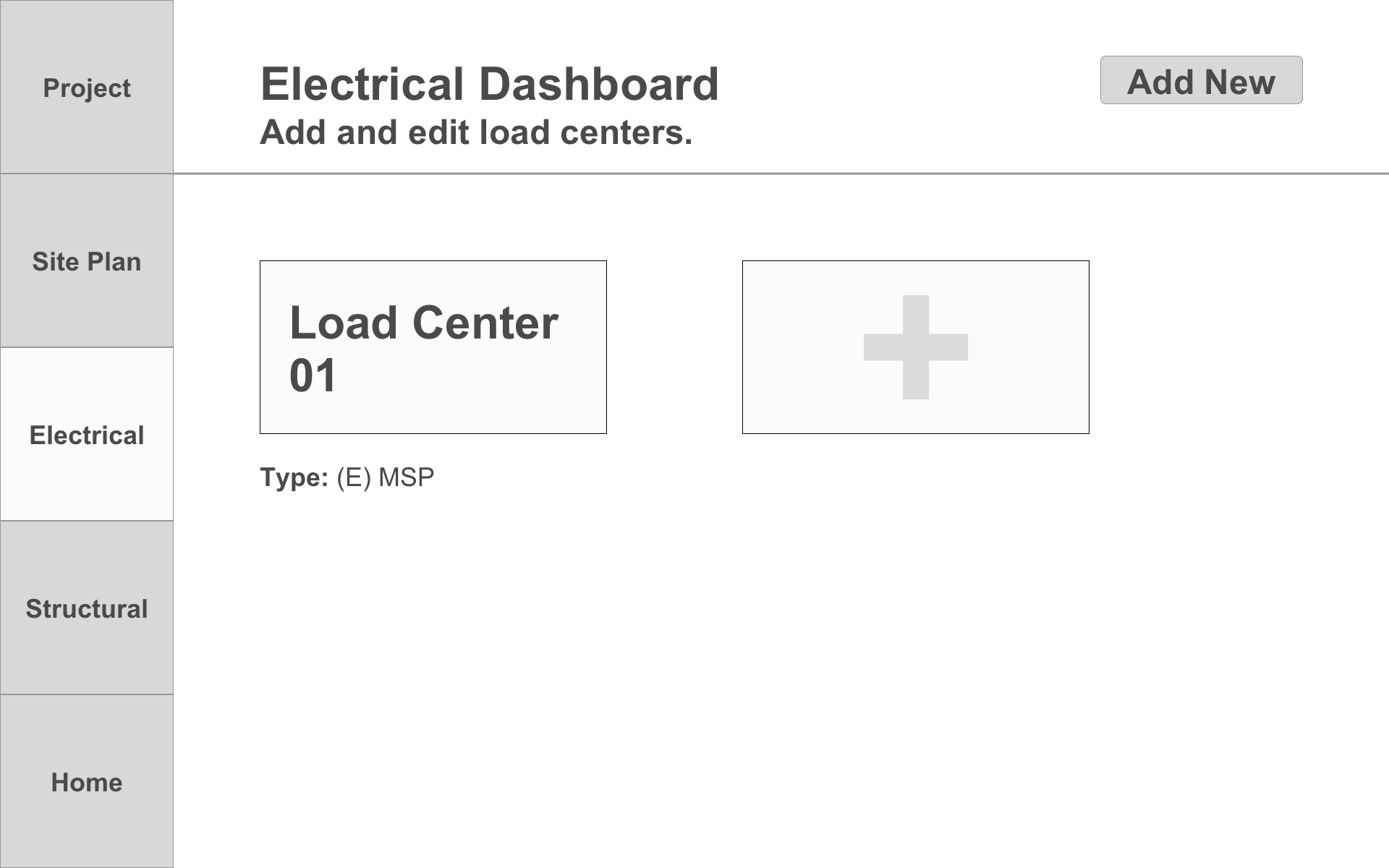

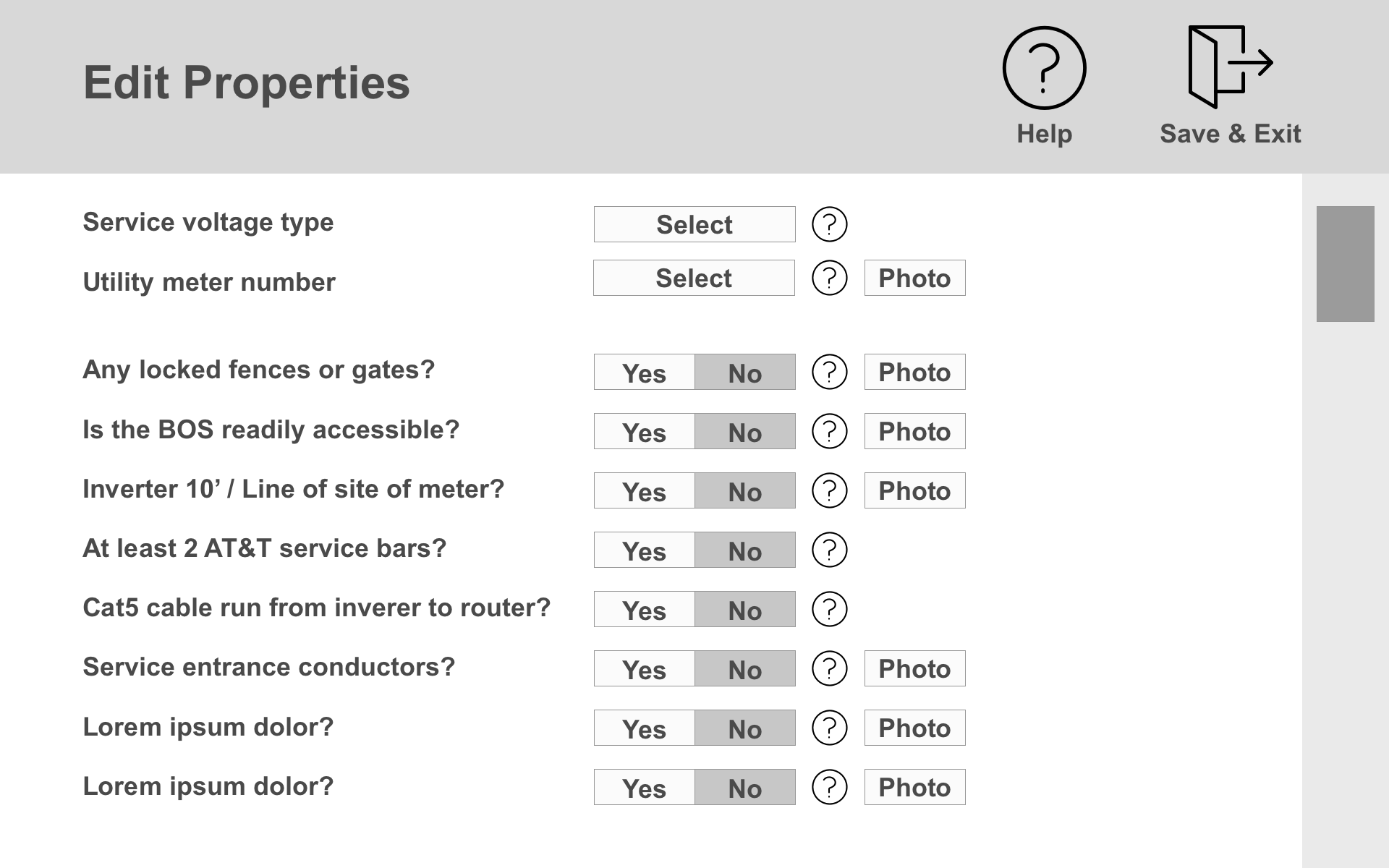

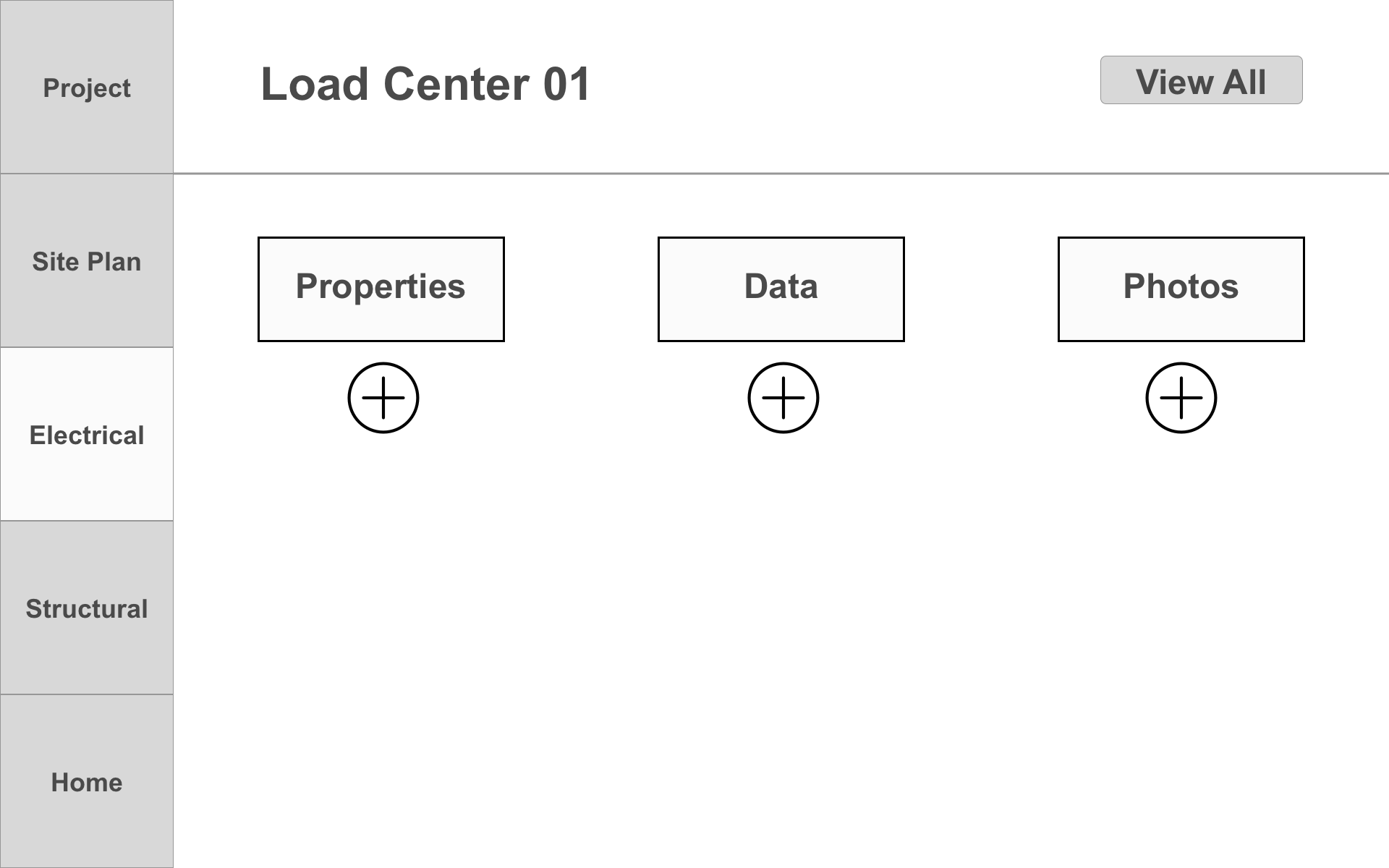

Digitizing the Home Visit

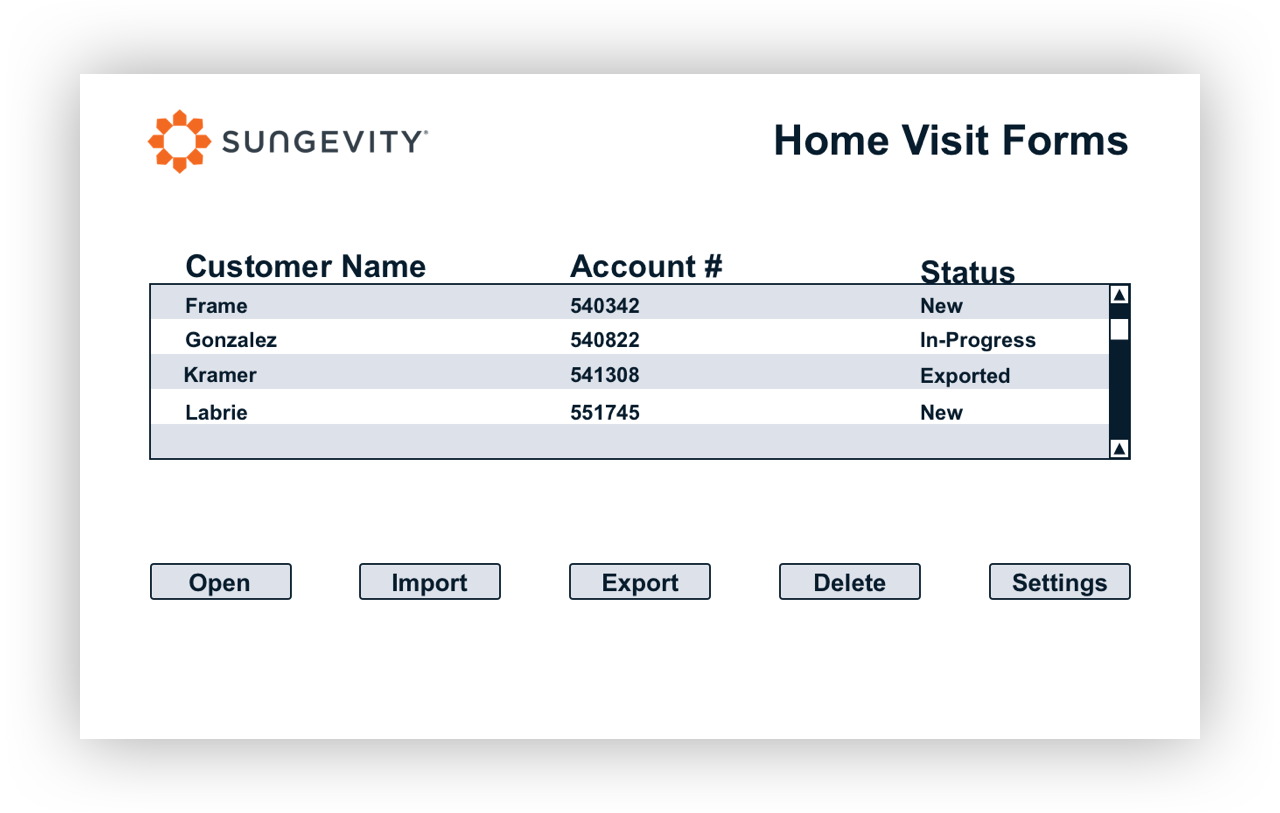

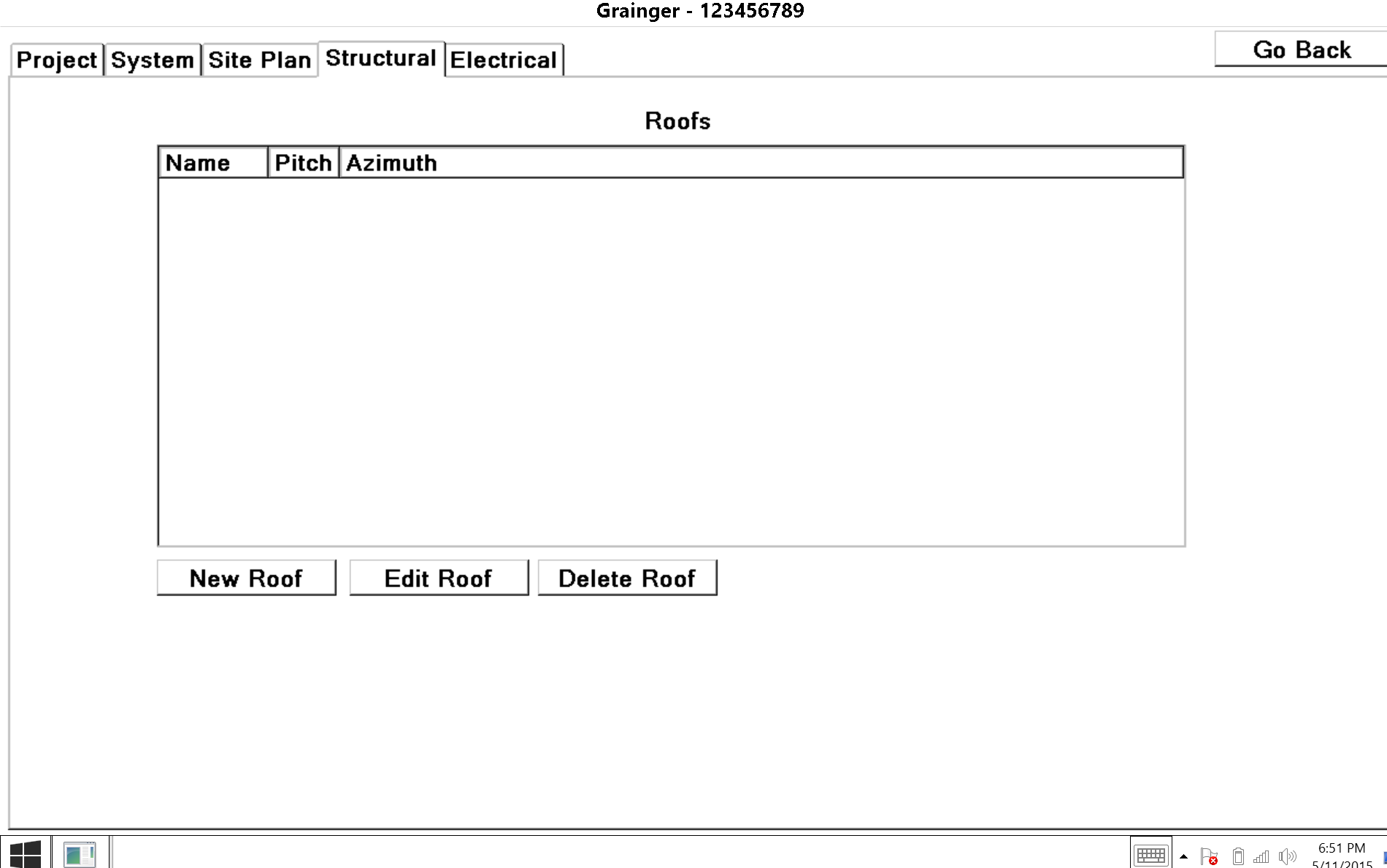

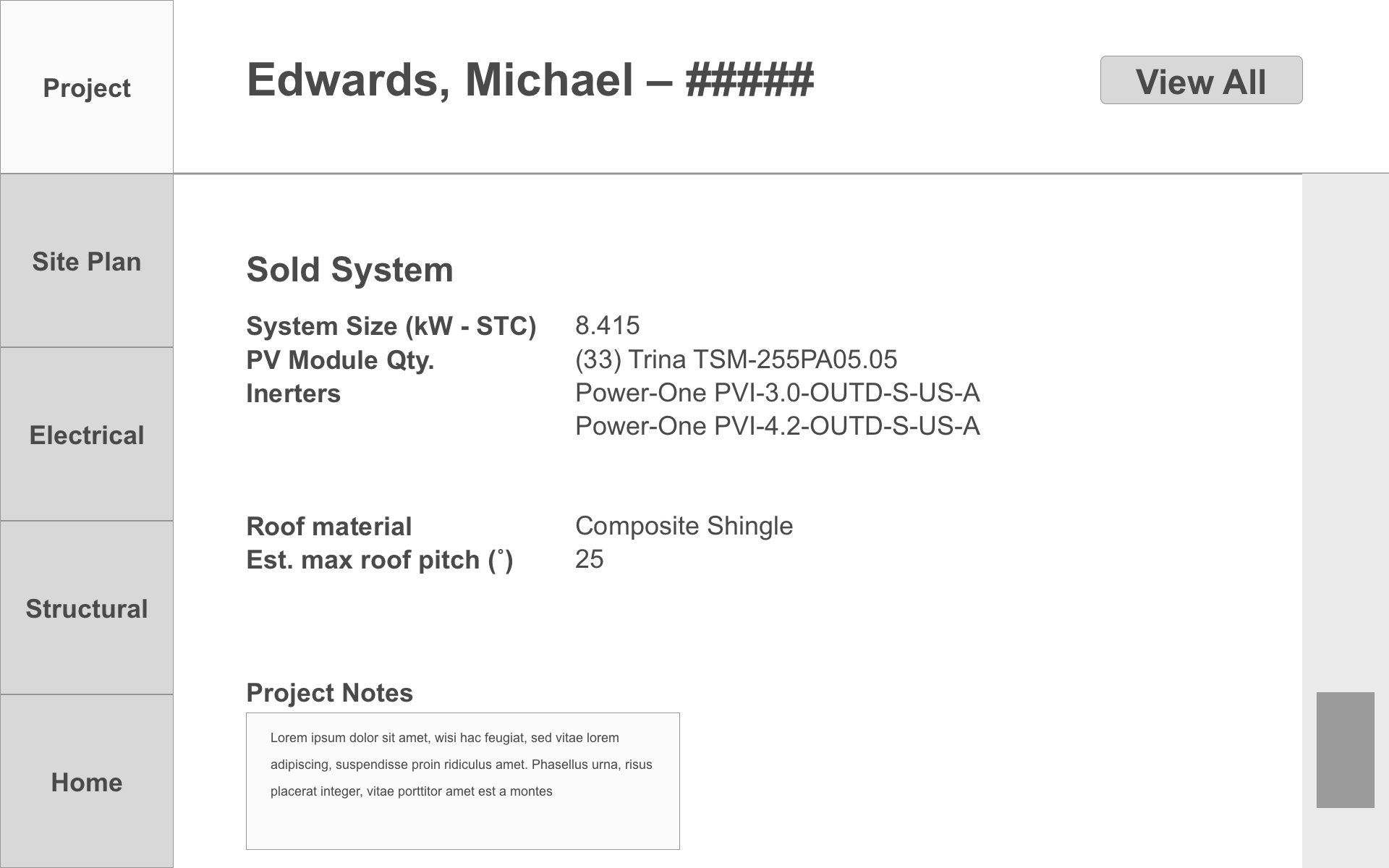

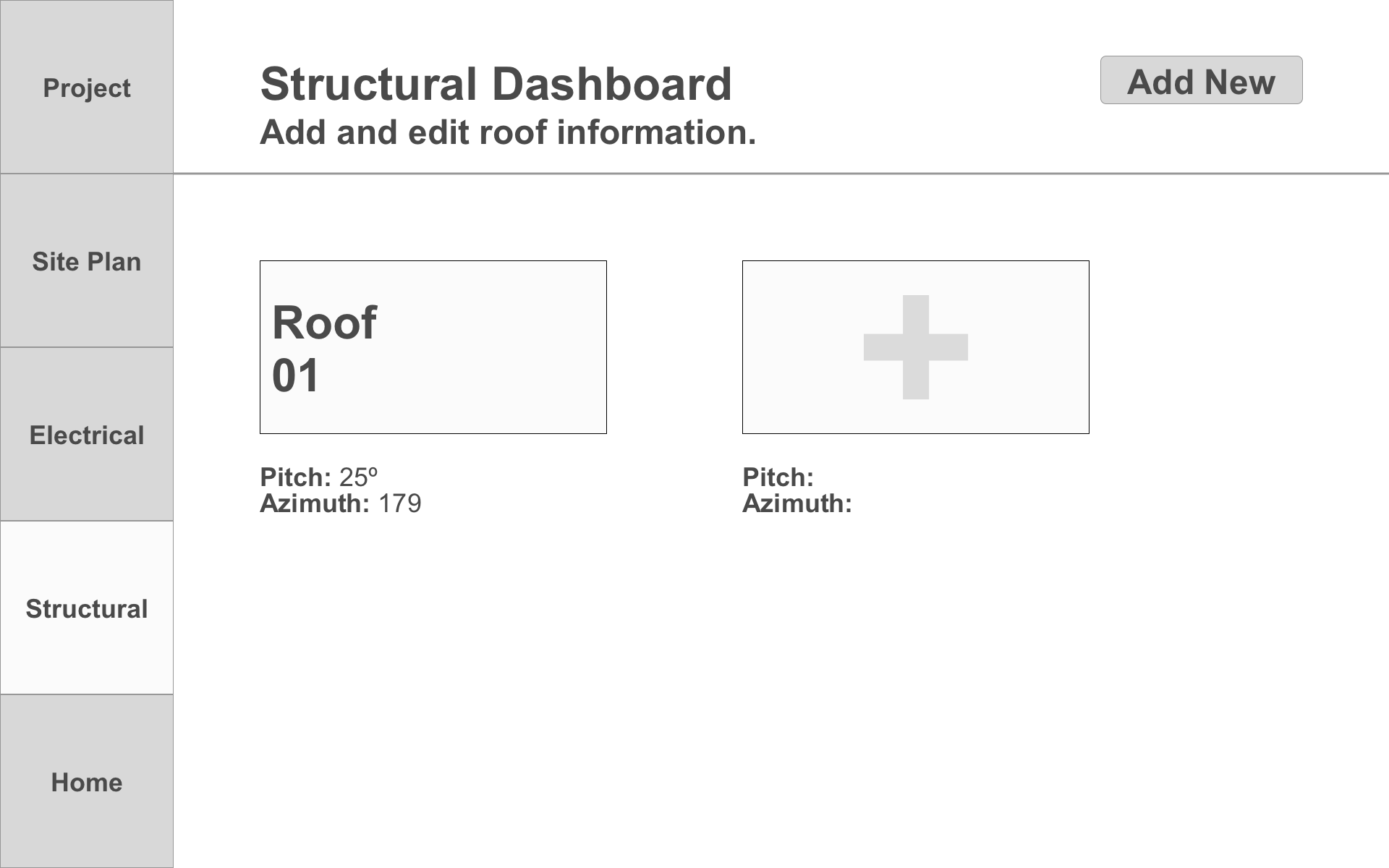

Most home visits require the same core information, with the primary difference between projects being quantity of roof faces. Simply building an intelligent, interactive form allowed us to significantly reduce our reliance on paper.

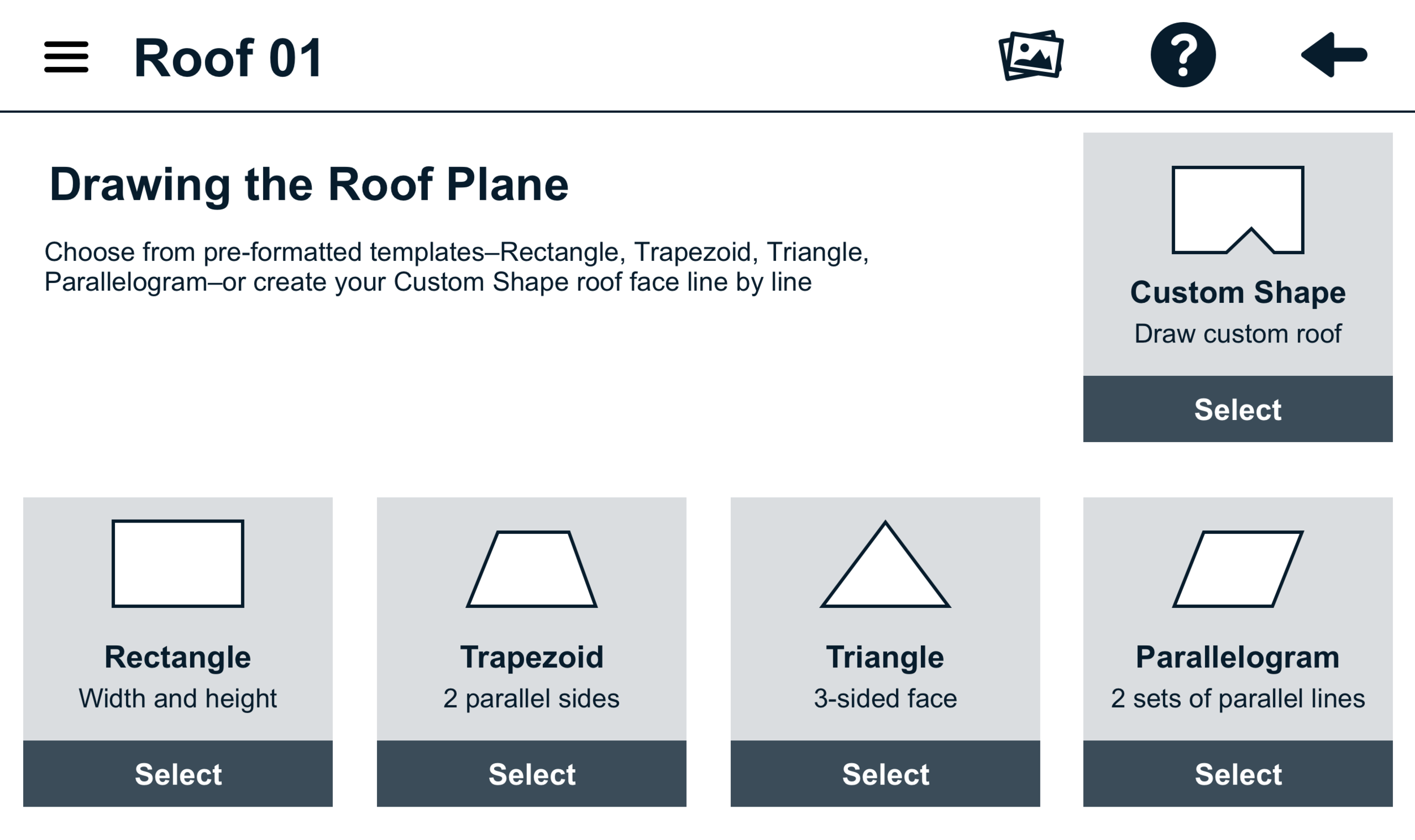

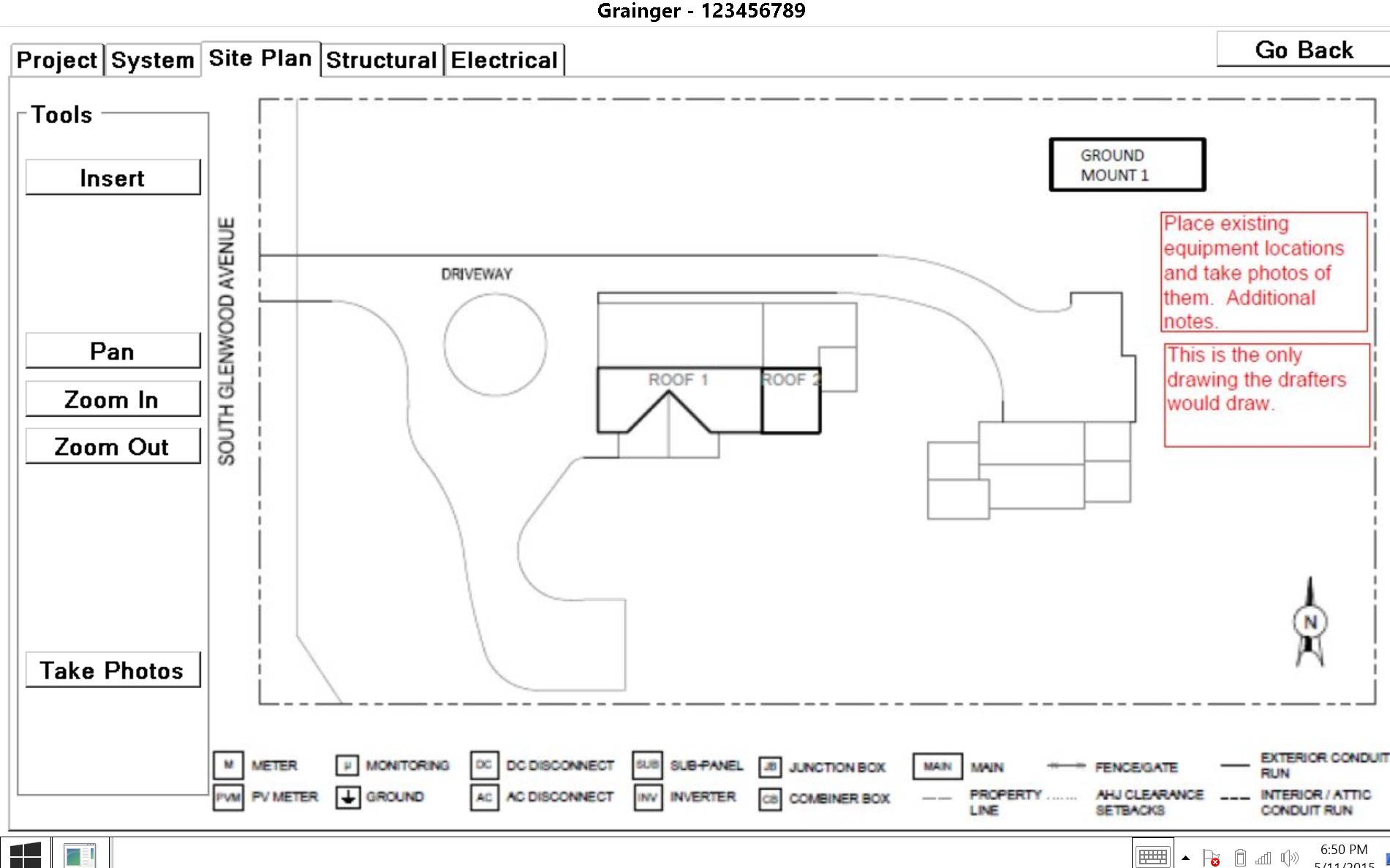

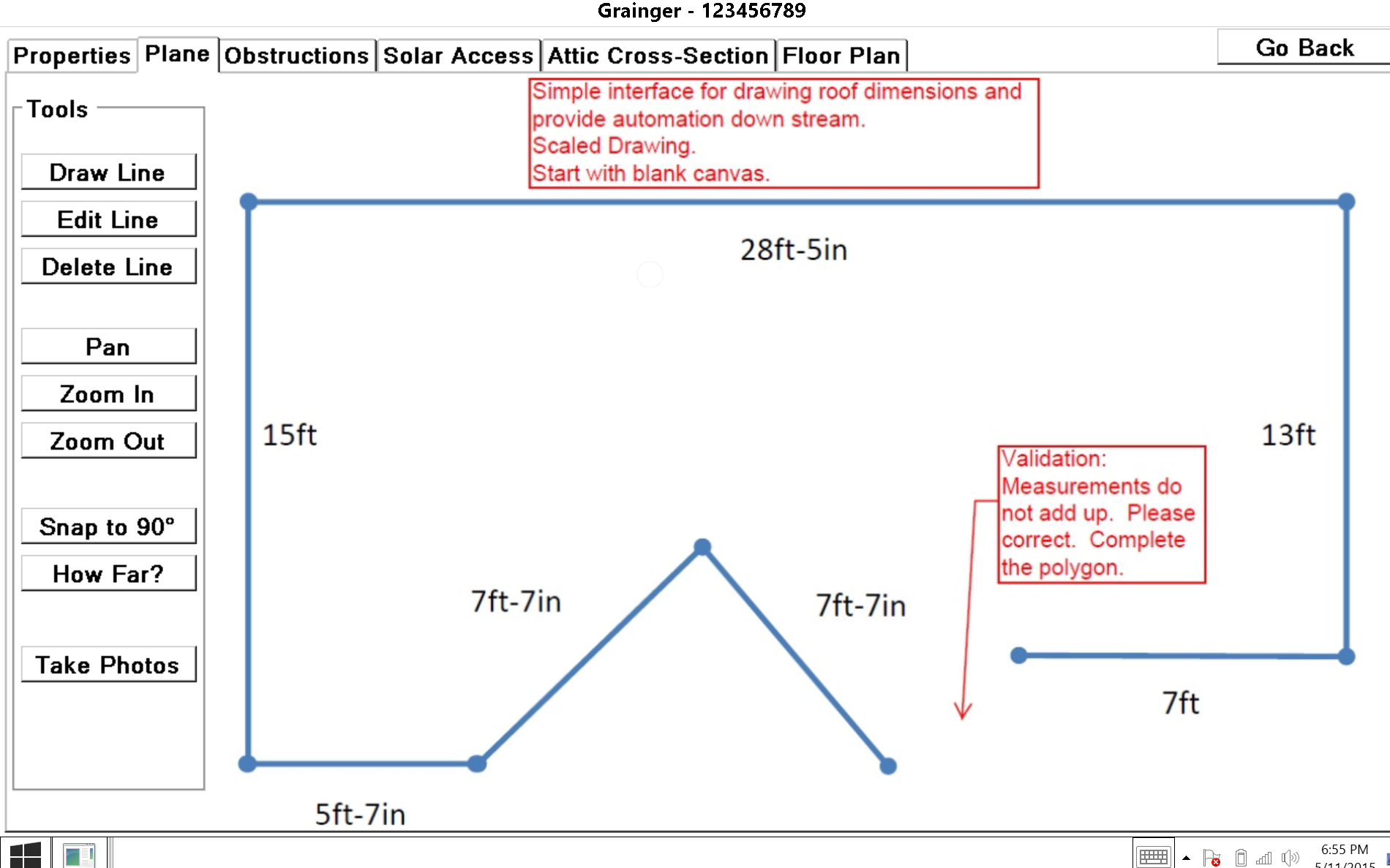

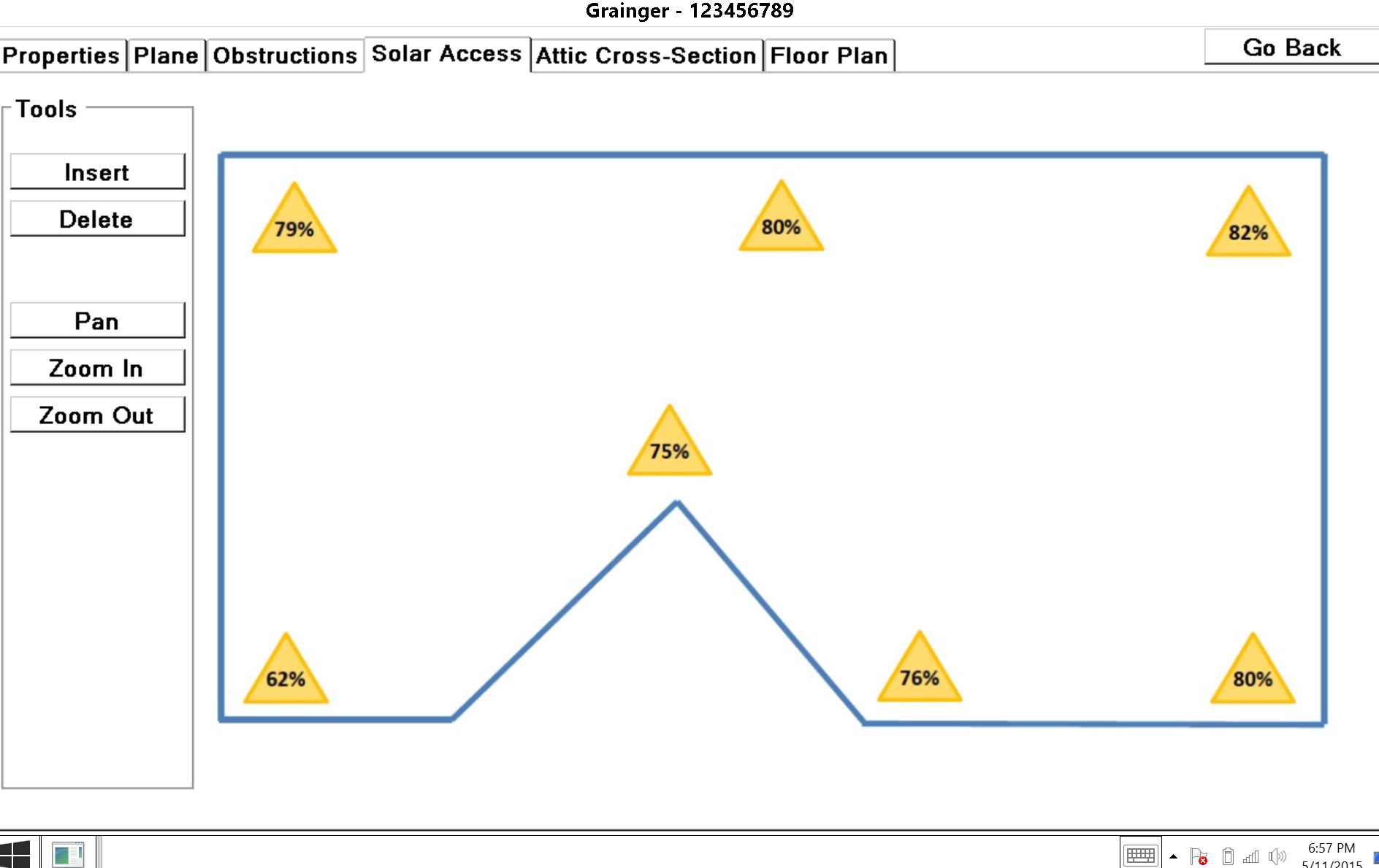

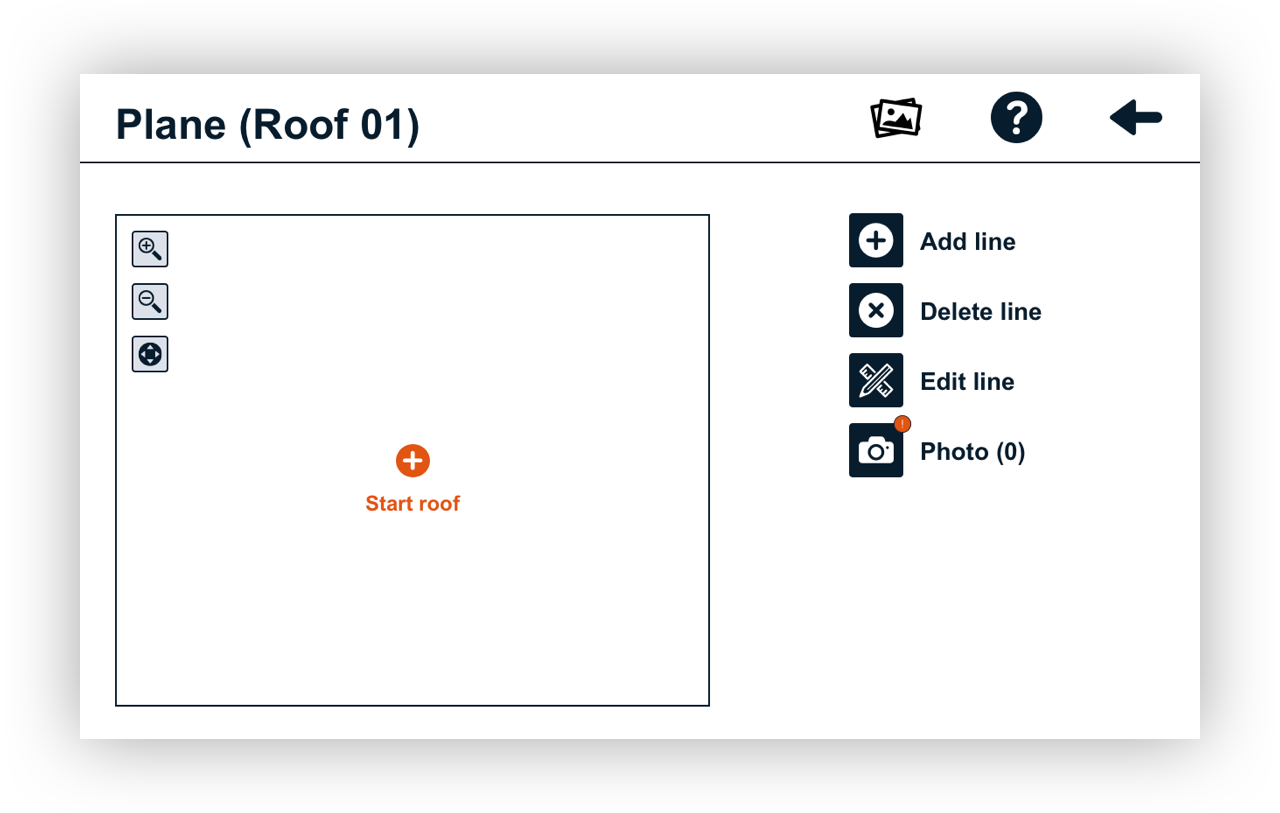

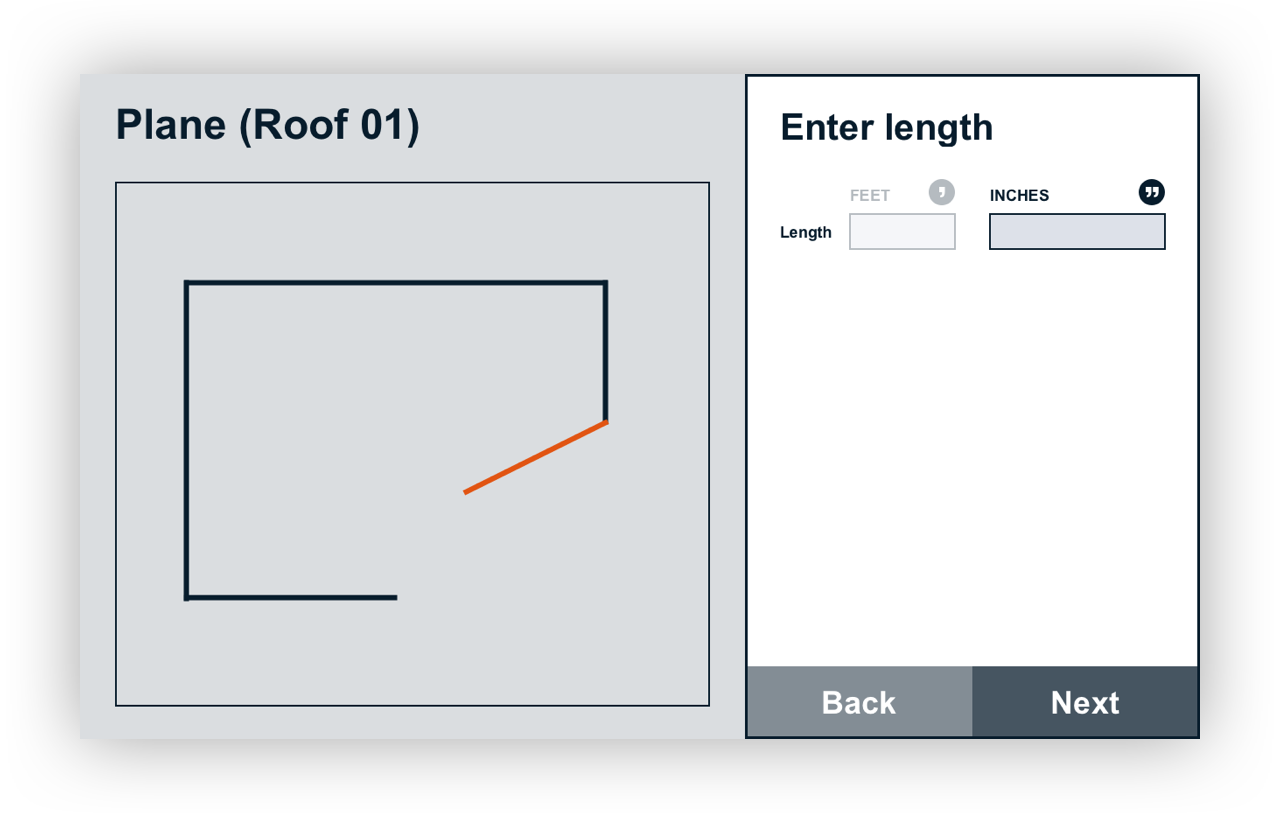

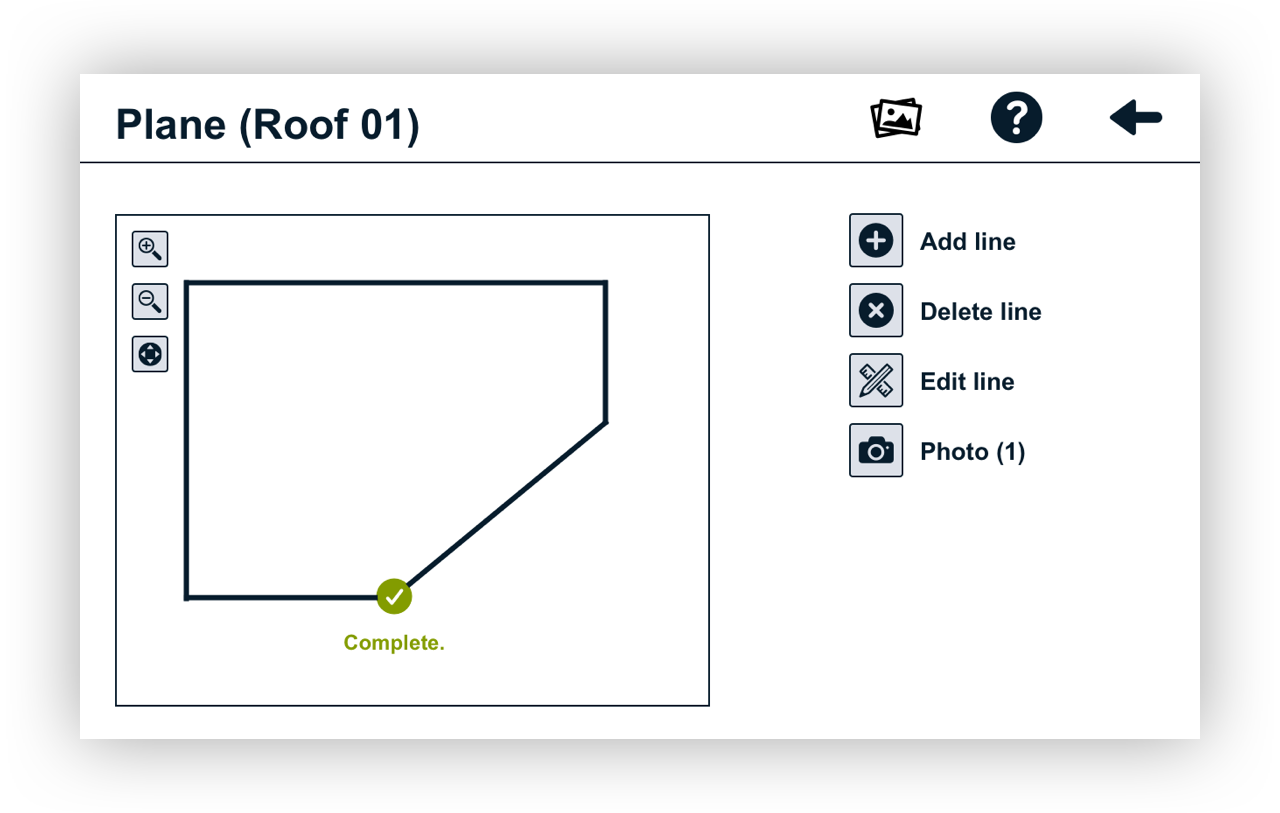

Expediting Roof Measurements

To cut down on the time Techs spent on the roof, we created common templates that reduced the number of measurements taken, and automated roof face drawings. For more abstract roof face shapes, we built a procedural interface that walked techs of all experience levels through the process.

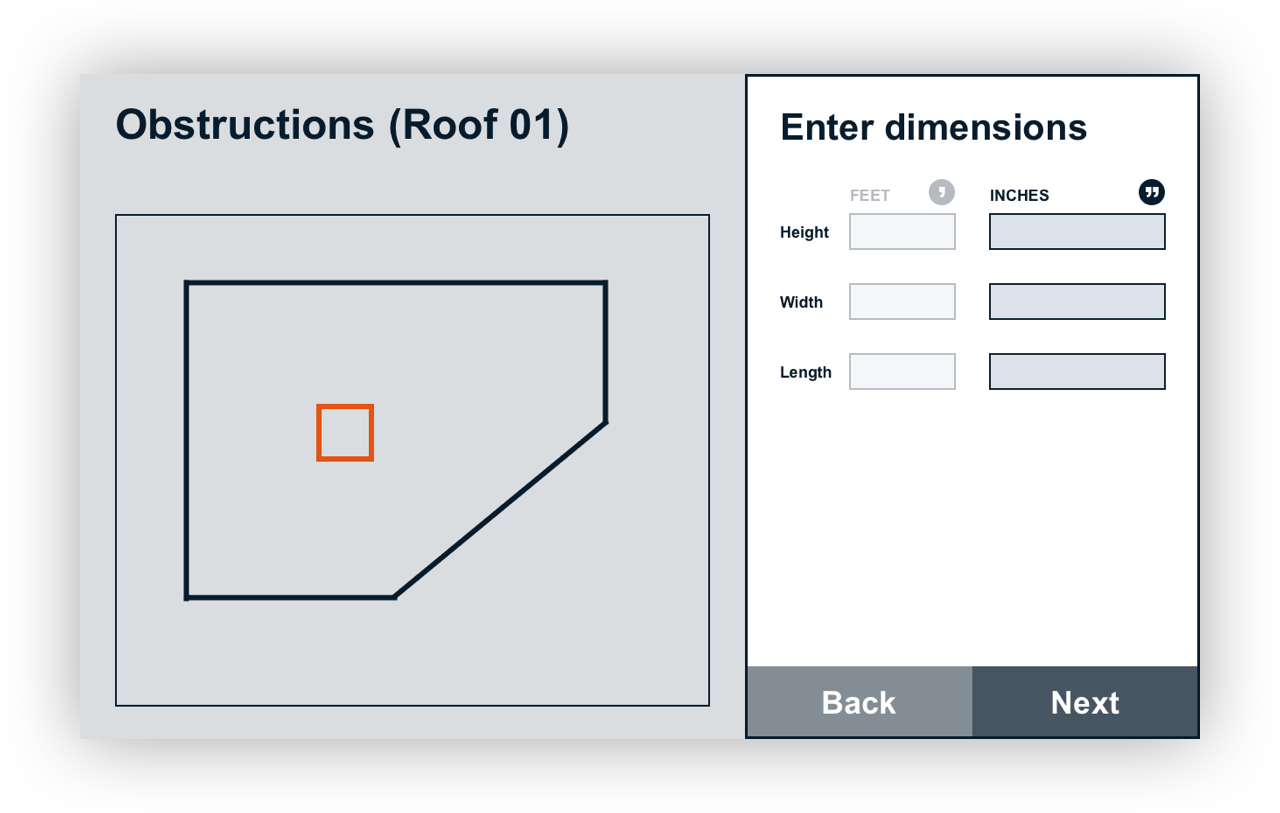

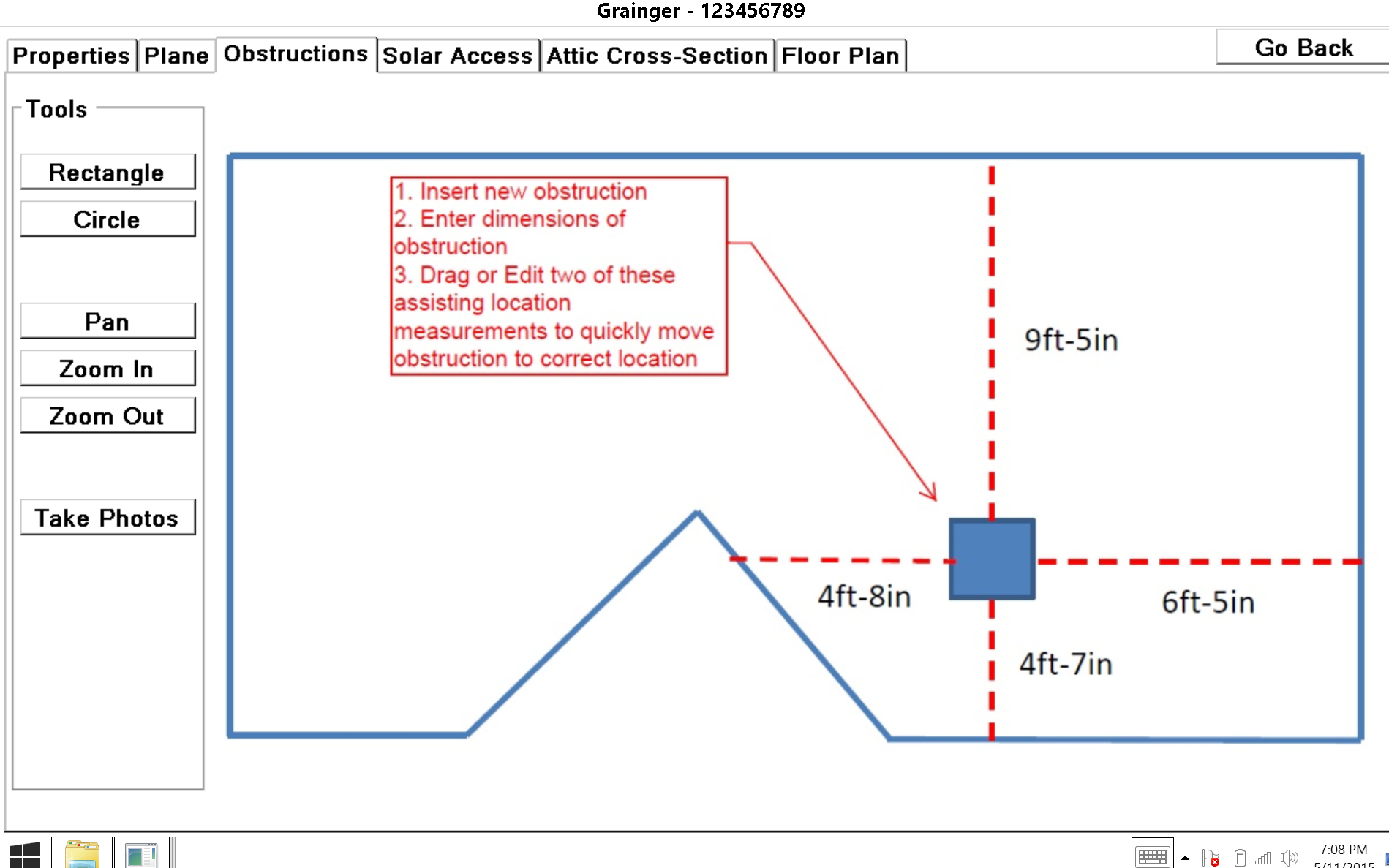

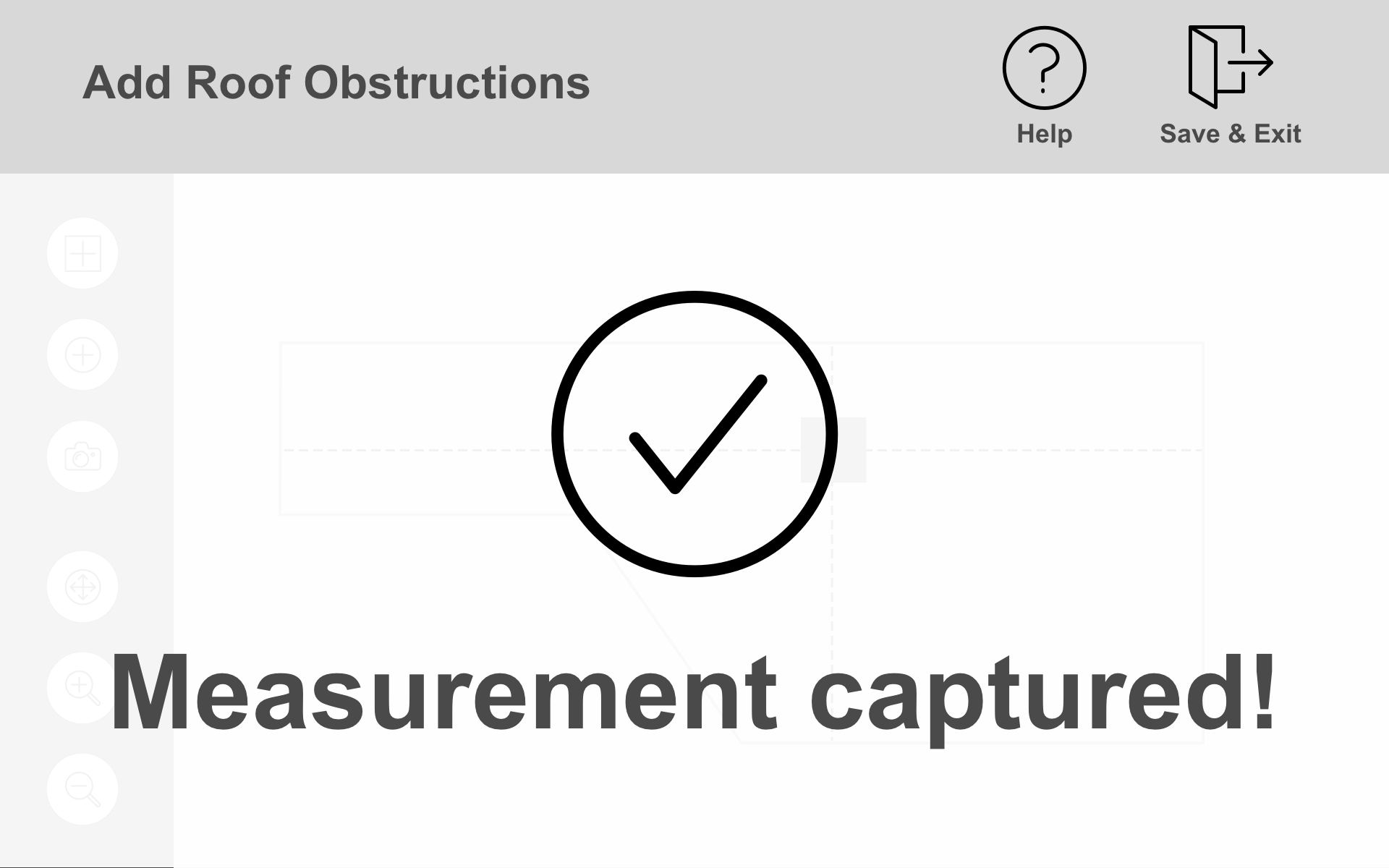

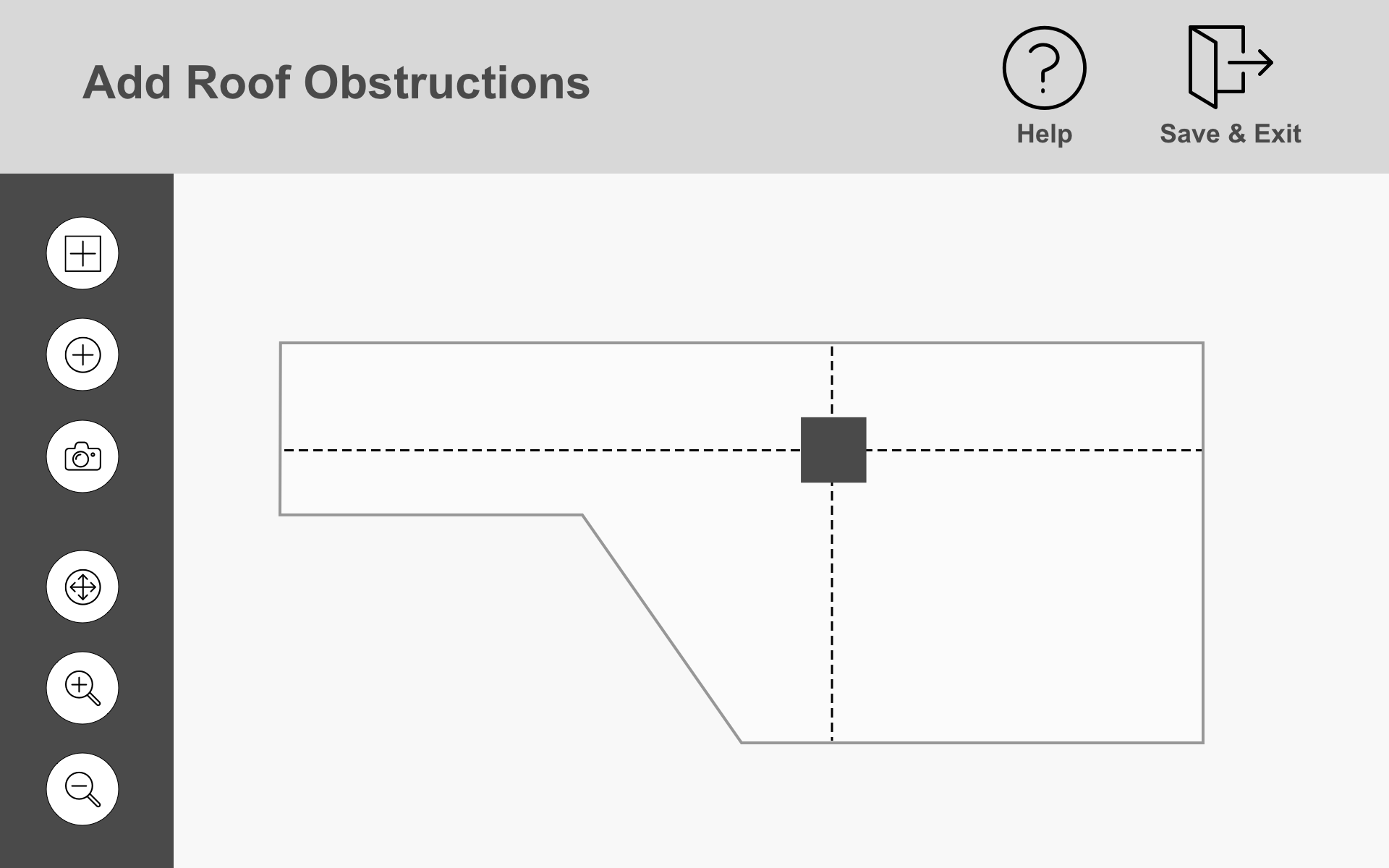

Adding Roof Obstructions

Roof obstructions such as vents and chimneys block sun exposure, and ultimately impact the energy output of solar panels if they are too close. We built a drag and drop interface similar to the roof templates for our Techs to communicate the size and placement of obstructions on the roof.

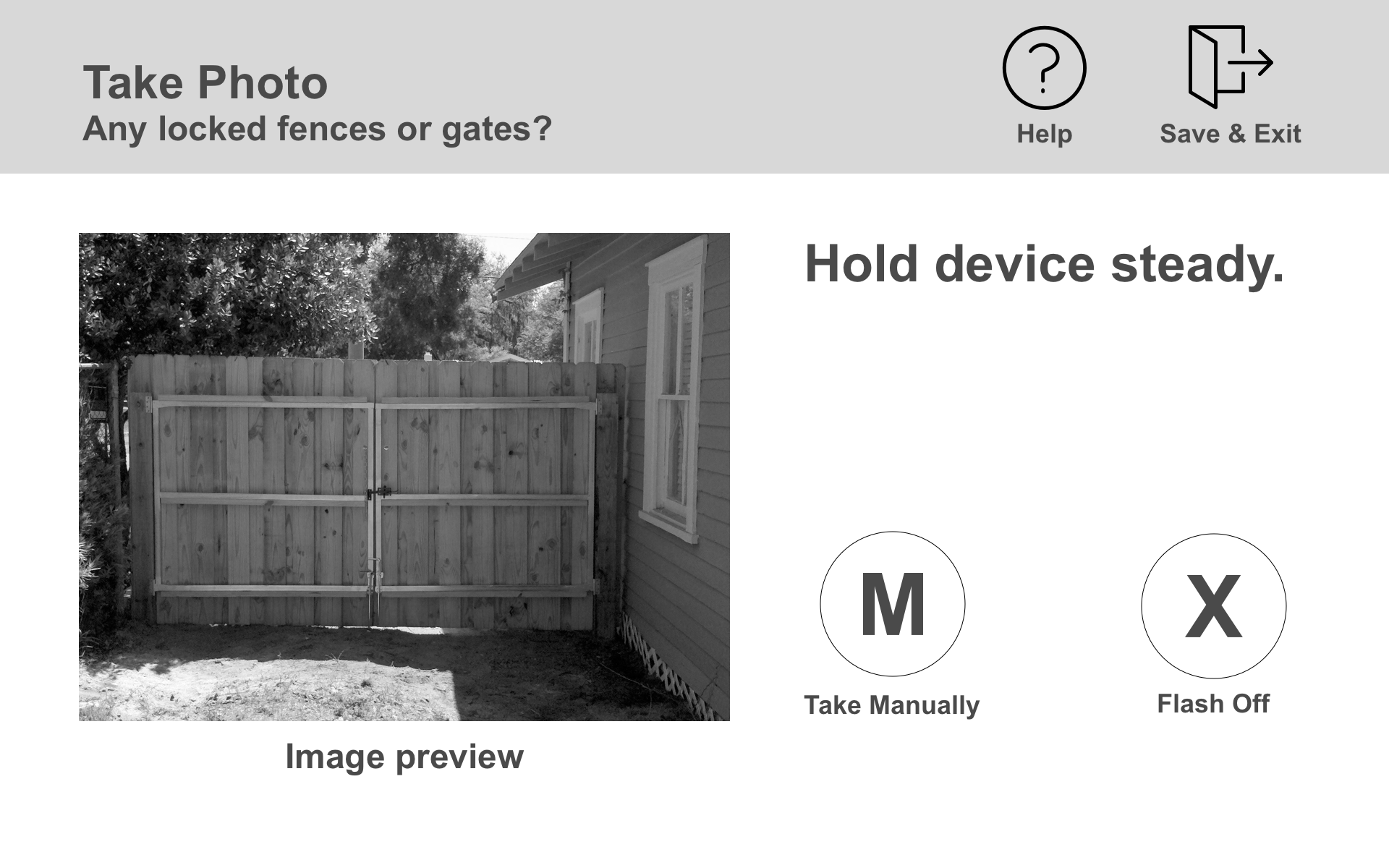

Organized Photo Checklist

The device came equipped with multiple cameras, eliminating the need for Techs to carry an additional digital camera. With BEAM, Techs now had a visual indication for items to capture, and immediate feedback for photo quality. This also gave us the ability to automatically organize and label photos for our Project Managers downstream.

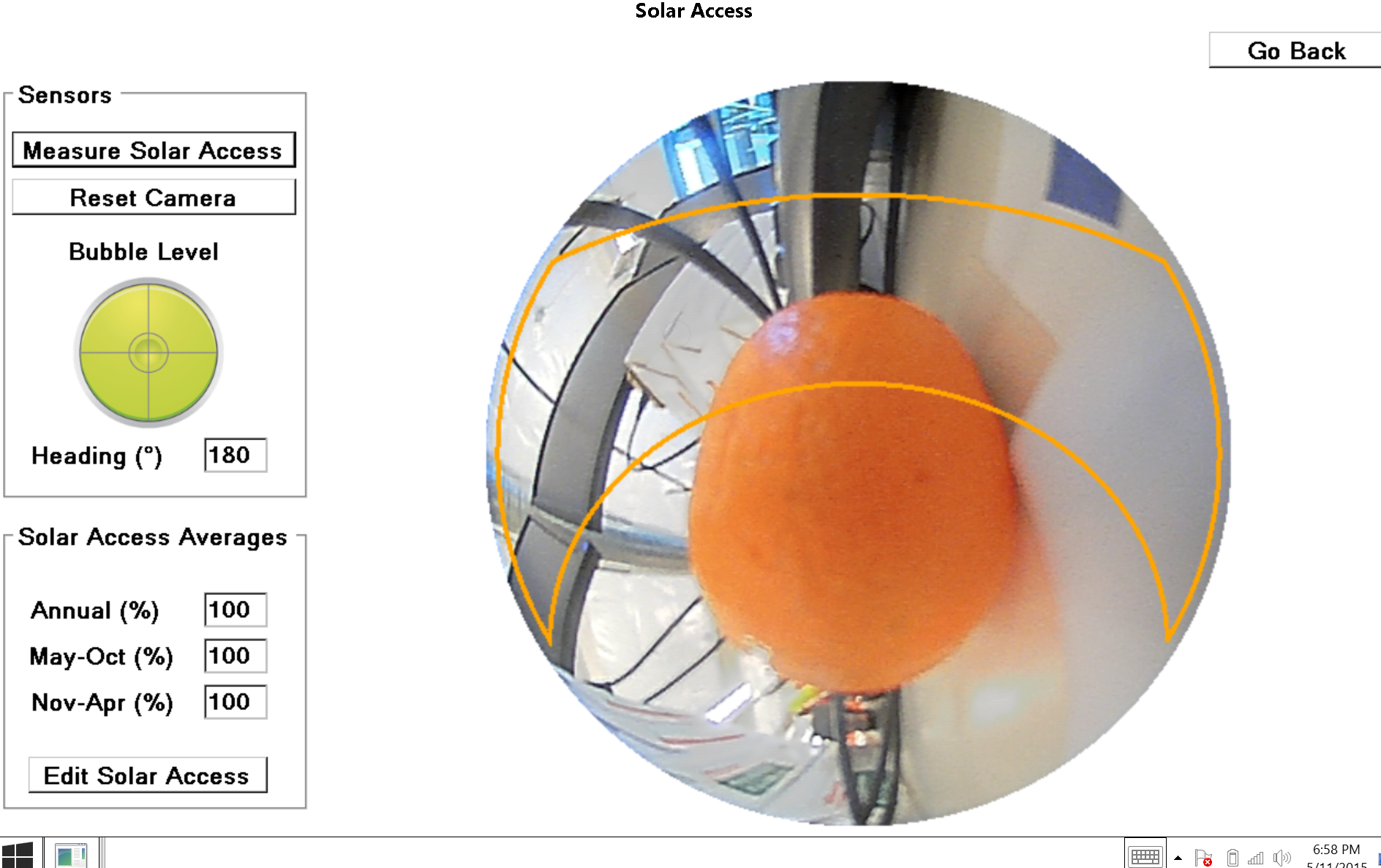

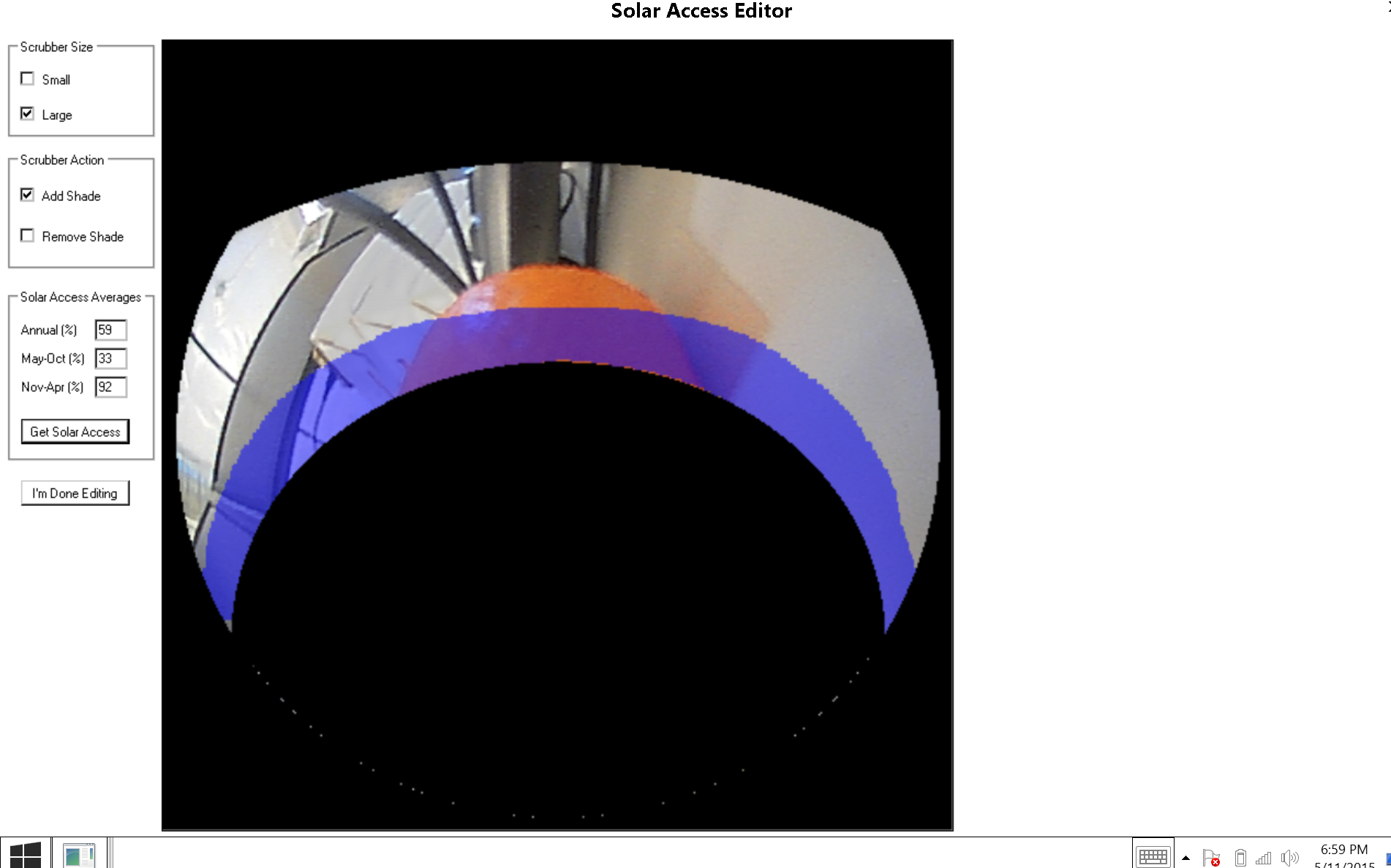

Building on the SunEye

After our first round of field research, we knew we wanted to iterate on BEAM's solar measurement capability. Users were quick to tell us the timer took too long, and we noticed the difficulty they had when working on steeper roof pitches. We made it easy to auto-capture measurements when the device was held stable and in the correct orientation. This dramatically improved the quality of solar readings.

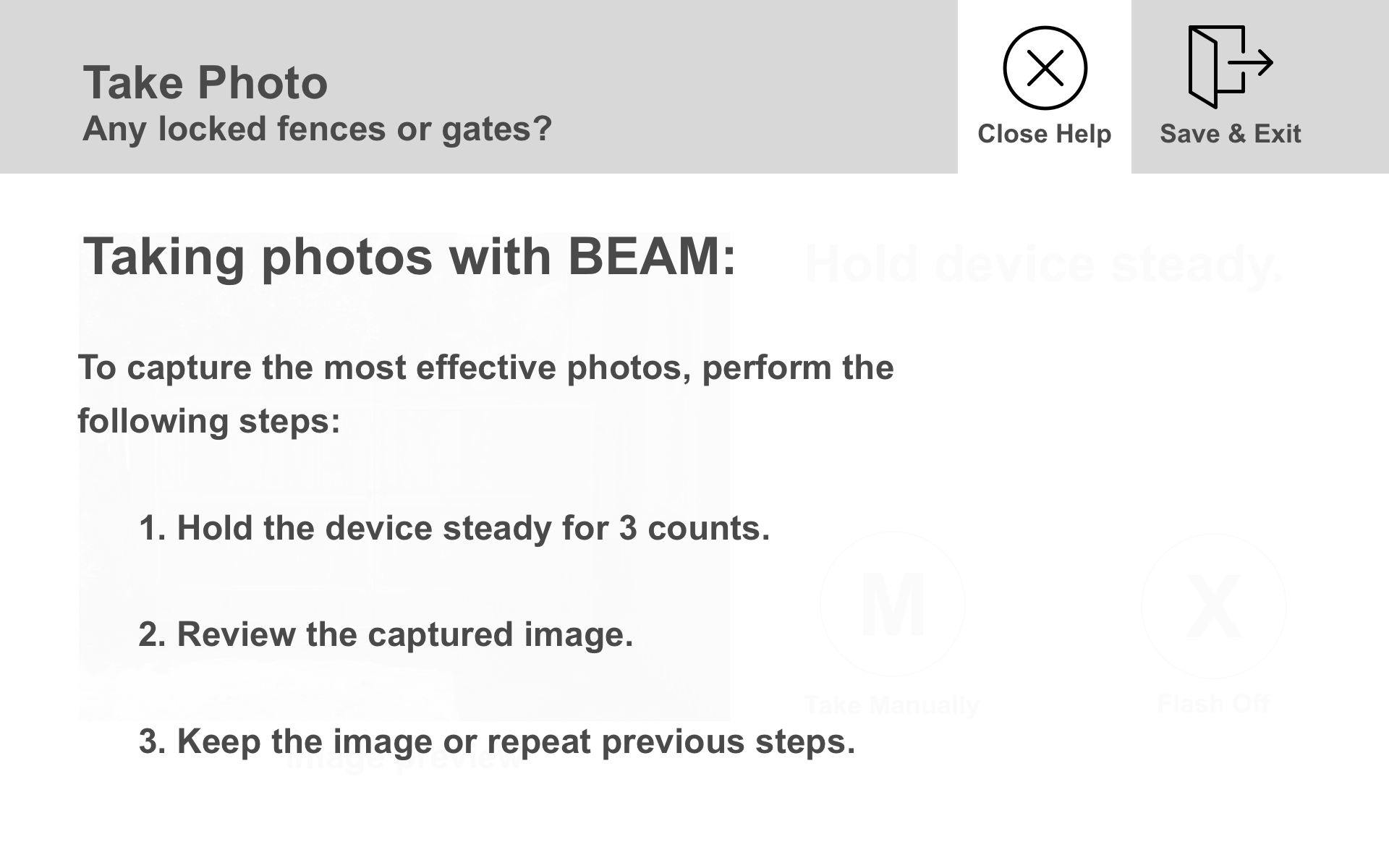

Assisting New Users

Home Visit Technicians have a high turnover. It’s largely an entry-level, transitional role held before becoming an Installer. To ensure our new techs could effectively use BEAM, we created Help screens that were populated with key terminology, and guidance on key tasks.

Upload / Download Anywhere

Since the Home Visit Technicians no longer required paper forms for their role, we wanted to make sure they could access and update projects from anywhere. We equipped BEAM with Bluetooth capability so projects could be downloaded and uploaded from anywhere. The real-time delivery of completed site assessment information significantly reduced the number of days it took to complete a customer’s installation.

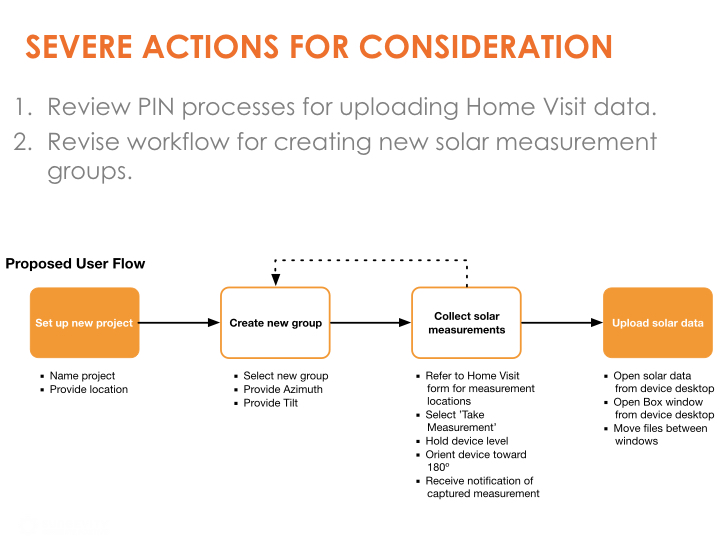

Phase 3 – Post-launch Updates

After delivering the product, we kept communication open with our network of installers to gather feedback on the most critical features and updates. Based on feedback and observation, we delivered three key updates:

The initial product prevented the use of finger-based, touch interaction in favor of what was perceived to be a more accurate stylus. In a software update, we unlocked touch functionality and monitored projects for an increase in user-error.

Measuring and drawing roof planes remained the most time consuming phase of the site visit. As a result, we created templates users could leverage to bypass the discrete steps necessary for custom roof faces.

The initial product provided no means for users to review the set of photos taken during the home visit. Occasional photos were taken by mistake, or delivered to the home office too blurry to make sense of. We updated the application with a Photo Album feature that directly tagged a photo to its associated metadata. This provided users with the ability to quickly review their site visit and note where any required photo was missing.

PROJECT IMPACT

BEAM had a significant impact on the site assessment experience for Home Visit Techs, as well as for our end customer. Beyond the measured data, the process we put in place to work directly with our users, the local installers, dramatically improved relations with our organization and set a new precedent for collaborating with our partners. The work we did has been consistently used as the new standard for new initiatives within the organization.

Device adoption within Sungevity's installer network of ~100%

Performance validation by DNV, a third party engineering firm and international certification body.

Time to install reduced 40%.

Error free rate improved 42%.

Reduced number of uploaded files from hundreds to one.

Consolidated many separate tools (paper, clipboard, camera, inclinometer, compass, SunEye) into one device.

Figures captured 4 months after product launch.